Hybrid Integrated Circuits (Hybrid IC): Definition, Examples, Uses & Advantages

Update Time: Nov 13, 2023 Readership: 1308

Contents

Hybrid Integrated Circuits (Hybrid ICs) represent a pivotal convergence of diverse electronic technologies, seamlessly combining the advantages of both monolithic integrated circuits and discrete component circuits. This innovative approach to circuit design has found extensive applications across various industries, offering a versatile solution for complex electronic systems. In this exploration, we delve into the definition, examples, uses, and advantages of Hybrid ICs, unraveling the intricacies that make them a cornerstone in modern electronic engineering.

What is Hybrid IC (Hybrid IC Definition)

Hybrid integrated circuits tap into the collaborative potential of semiconductor integration technology and thin (thick) film technology. These circuits bring together thick or thin film components, along with their interconnections, onto a substrate using a film-forming process. What sets hybrid integrated circuits apart is their fusion on a shared substrate, where discrete semiconductor chips, monolithic integrated circuits, or micro components are intricately blended and then packaged together.

What is Hybrid IC Technology

In the manufacturing of hybrid integrated circuits, two commonly employed film deposition technologies are screen printing sintering and vacuum film deposition. The film generated through screen printing sintering is termed thick film, typically exceeding a thickness of 15 micrometers. In contrast, the film produced by vacuum film deposition is referred to as thin film, with thickness ranging from several hundred to several thousand angstroms.

If the passive network within a hybrid integrated circuit predominantly consists of thick film, it is categorized as a thick-film hybrid integrated circuit. Conversely, if it incorporates a thin-film network, it is classified as a thin-film hybrid integrated circuit. To address the demands of miniaturization and integration in microwave circuits, there is a specific category known as microwave hybrid integrated circuits.

These microwave circuits, categorized based on the concentration and distribution of component parameters, further branch into lumped parameter and distributed parameter microwave hybrid integrated circuits. Lumped parameter circuits share structural similarities with conventional thick or thin-film hybrid integrated circuits but require heightened precision in component dimensions.

Conversely, distributed parameter circuits differ; their passive networks do not consist of visibly distinguishable electronic components but are entirely constructed by microstrip lines. Due to the stringent precision requirements for microstrip lines, thin film technology is predominantly employed in the fabrication of distributed parameter microwave hybrid integrated circuits.

Advantages of Hybrid Integrated Circuits (Hybrid IC)

In comparison to traditional discrete component circuits, hybrid integrated circuits exhibit notable advantages such as heightened assembly density, superior reliability, and enhanced electrical performance. Distinguishing themselves from monolithic integrated circuits, they offer a more flexible design, streamlined processes, and facilitate convenient multi-variety and small-batch production. Furthermore, hybrid integrated circuits feature a broad spectrum of component parameters, ensuring high precision, excellent stability, and the capability to withstand higher voltages and increased power demands.

Disadvantages of Hybrid Integrated Circuits/Hybrid IC

Hybrid integrated circuits (ICs) have some disadvantages compared to other types of ICs, and these drawbacks may impact their use in certain applications.

Cost: Hybrid ICs can be more expensive to manufacture compared to monolithic ICs (integrated circuits fabricated on a single semiconductor substrate). The hybrid manufacturing process involves assembling individual components onto a substrate, which can increase production costs.

Size and Weight: Hybrid ICs may be larger and heavier than monolithic ICs with similar functionality. This is because hybrid ICs often involve the integration of discrete components (such as resistors, capacitors, and transistors) along with the semiconductor devices.

Limited Integration: Hybrid ICs may have limitations in terms of the level of integration achievable. Monolithic ICs, on the other hand, can integrate a large number of components on a single chip, leading to higher levels of functionality and miniaturization.

Reliability Concerns: The assembly process of hybrid ICs involves connecting different components, and this can introduce reliability concerns, particularly in terms of solder joints and wire bonds. The connections may be more susceptible to mechanical stresses, temperature variations, and other environmental factors.

Performance Variability: Due to the involvement of discrete components, the performance characteristics of hybrid ICs may exhibit more variability compared to monolithic ICs. This variability can be a concern in applications that demand precise and consistent performance.

Limited Frequency Range: Hybrid ICs may not perform as well at very high frequencies compared to monolithic ICs. The additional parasitic elements introduced by the discrete components can limit the frequency response.

Customization Challenges: While hybrid ICs offer some flexibility for customization by adding discrete components, the process of customization can be more complex and costly compared to designing a custom monolithic IC.

Despite these disadvantages, hybrid ICs have their own set of advantages, such as the ability to integrate various technologies, mix different materials, and combine analog and digital components.

Hybrid Circuit Diagram

Hybrid system circuit diagram

Schematic of hybrid circuit breaker

Hybrid integrated circuit overview diagram

Hybrid Integrated Circuits (Hybrid IC) Examples

Hybrid integrated circuit - low noise amplifier

thick film hybrid integrated circuit

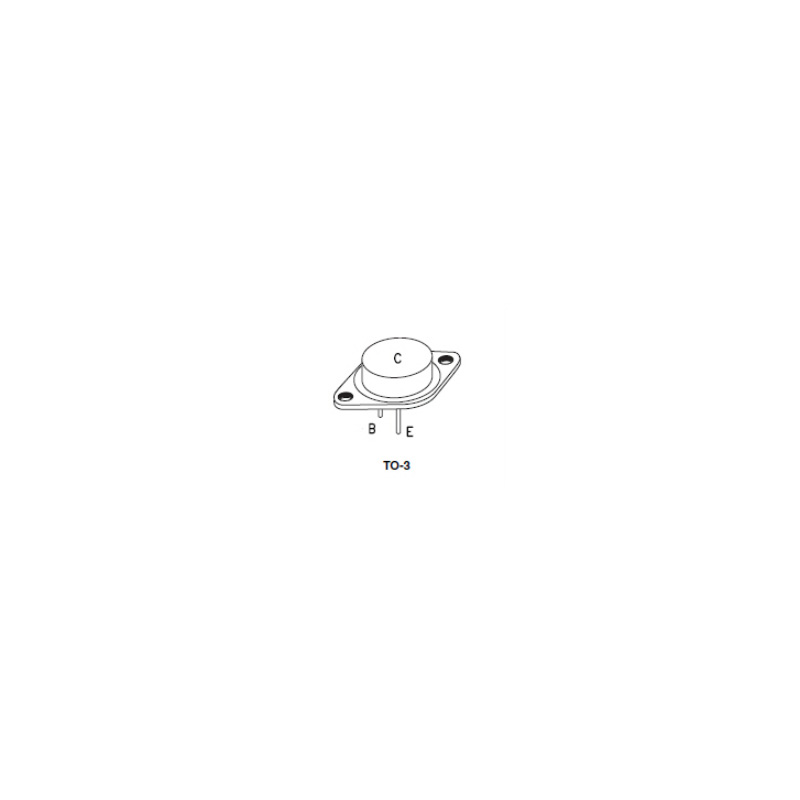

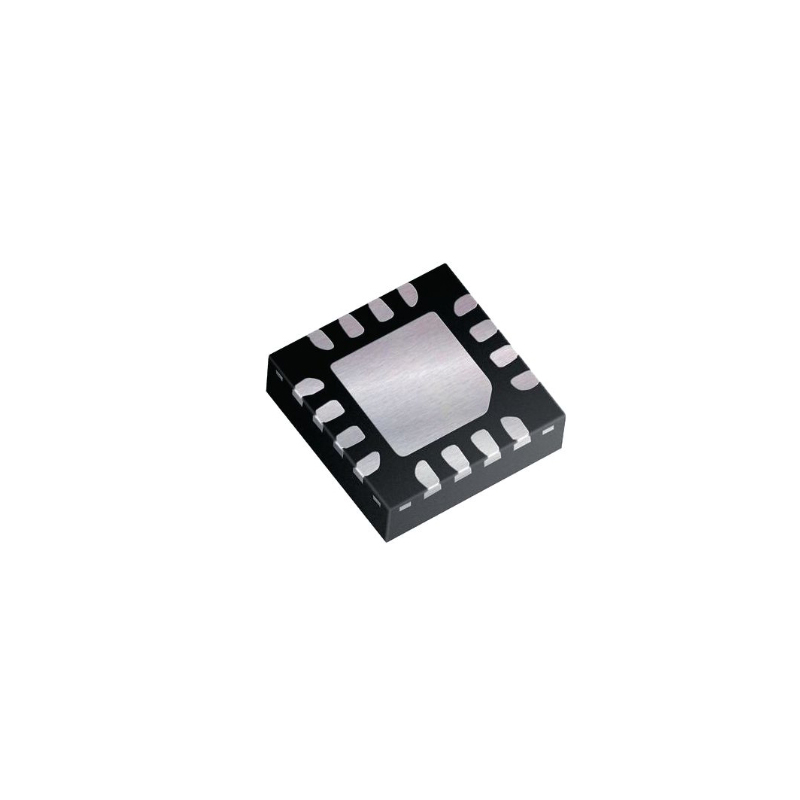

Example of an Hybrid Integrated Circuit Package

Hybrid microwave integrated circuits

Comparison Between Monolithic and Hybrid IC

A monolithic integrated circuit stands out for having the entire circuit built on a singular piece of silicon or another semiconductor material. Typically, this compact circuit is then enclosed within a package featuring connecting leads for enhanced functionality.

On the other hand , a hybrid circuit takes shape with a substrate, often crafted from ceramic, hosting one or more silicon chips. These chips can encompass monolithic integrated circuits, individual diodes, or transistors. The substrate serves as a platform for the integration of resistors and conductive tracks, complemented by additional components soldered onto the tracks to craft a comprehensive circuit. In certain instances, a hybrid circuit adopts mixed technology, seamlessly incorporating GaSs chips alongside silicon chips within the same assembly. This adaptability enables the fusion of diverse technologies, optimizing the performance and capabilities of the hybrid circuit.

|

Criteria |

Monolithic IC |

Hybrid IC |

|

Integration |

Entire circuit on a single semiconductor chip |

Combines multiple chips or technologies on a substrate |

|

Components |

Limited types of components on a single chip |

Diverse components (e.g., resistors, capacitors) can be integrated |

|

Customization |

Limited customization due to single-chip design |

Allows for customization with a mix of technologies and components |

|

Complexity |

Limited complexity due to single-chip structure |

Higher complexity with the integration of multiple elements |

|

Performance |

Optimized for specific applications |

Versatile and adaptable to various applications |

|

Size |

Smaller footprint due to single-chip design |

Can be larger due to the integration of multiple components |

|

Cost |

Potentially lower manufacturing costs |

Costs may vary based on the complexity and customization |

|

Reliability |

Generally high reliability for specific functions |

Reliability may depend on the integration and assembly process |

|

Applications |

Common in digital and certain analog applications |

Widely used in analog, RF, and specialized applications |

|

Technology Development |

Advances in monolithic technology continue |

Hybrid technology evolves with integration trends |

Hybrid Integrated Circuits (Hybrid IC) Packaging

Hybrid integrated circuit packaging involves enclosing the hybrid circuit in a protective housing or package. Different packaging formats are used based on the application requirements and the specific characteristics of the hybrid integrated circuit.

-

SIP (System in Package): SIP packaging involves integrating multiple functional blocks or entire systems into a single package. It enhances miniaturization and can include a combination of different technologies.

-

DIP (Dual In-line Package): DIP is a traditional packaging style where the hybrid integrated circuit is enclosed in a rectangular housing with two parallel rows of leads extending from the sides. It is a widely used and standardized packaging format.

-

SOP (Small Outline Package): SOP is a compact and space-efficient packaging style. It is similar to DIP but with smaller dimensions, making it suitable for applications where space is a critical factor.

The choice of packaging depends on factors such as the intended use, size constraints, environmental considerations, and the need for integration with other components or systems.

Hybrid Integrated Circuits (Hybrid IC) Applications

Hybrid integrated circuits play an important role in the fields of analog circuits and microwave circuits, and are widely used in special circuits with higher voltages and larger currents. Generally speaking, the application fields of hybrid integrated circuits are very wide, covering analog circuits, microwave circuits and special circuits with higher voltage and larger current. Its applications in communications, radar, audio processing, power management and other fields provide high-performance and high-reliability solutions for various electronic devices.

|

Application |

Specific Applications |

Main Functions |

|

Analog Circuits |

Data Conversion Circuits: Portable radios, airborne radios, etc. |

High-precision data conversion, ensuring accurate communication signals |

|

Audio Processing Circuits: Amplification, filtering, equalization, etc. |

Audio signal processing, enhancing the performance of audio devices |

|

|

Sensor Interface Circuits: Connecting and processing various sensor signals |

Sensor signal interfaces, widely used in industrial automation and environmental monitoring |

|

|

Microwave Circuits |

RF Front-End: RF amplifiers, mixers, frequency synthesizers in communication systems |

RF signal conditioning and transmission, ensuring the performance of communication systems |

|

Radar Systems: Microwave transmission, reception, and signal processing |

Radar signal processing, improving radar performance and target detection accuracy |

|

|

Microwave Transmit-Receive Modules: Satellite communication, radar, navigation systems, etc. |

Microwave signal transmission and reception, applied in satellite communication, navigation, and remote sensing |

|

|

Specialized Circuits |

Power Management Circuits: Power conversion and regulation circuits |

Efficient power management, ensuring stable power supply for electronic devices |

|

Driver Circuits: Motor drive circuits, power switch circuits, etc. |

Control of high-power devices, such as motor and power drive circuits |

|

|

Power Electronics: Inverters, converters, widely used in industrial control and power systems |

Efficient power conversion, applied in industrial control systems and power electronic devices |

Hybrid Integrated Circuits (Hybrid IC) Fabrication Process

To facilitate automated production and seamless integration into electronic devices, the manufacturing process of hybrid integrated circuits relies on standardized insulating substrates. The predominant substrates utilized are rectangular glass and ceramic, providing a canvas for the creation of one or several functional circuits. The production sequence commences by crafting thin-film passive components and interconnection lines on the substrate, culminating in the formation of a passive network. Subsequently, semiconductor devices or semiconductor integrated circuit chips are affixed onto the substrate.

The construction of thin-film passive networks involves the application of photolithography and film-forming techniques. Following a meticulously defined process sequence on the substrate, conductive, semiconductor, and dielectric films, exhibiting various shapes and widths, are meticulously generated. These film layers are intricately combined to fashion diverse electronic components and interconnection lines. Upon the completion of the entire circuit on the substrate, lead wires are meticulously soldered. If deemed necessary, a protective layer is applied to shield the circuit. In the final stage, the circuit is encapsulated within an outer casing, thereby culminating in the creation of a fully assembled hybrid integrated circuit.

Read More: Hybrid integrated circuits fabrication

Final Words

Hybrid Integrated Circuits stand as a testament to the dynamic evolution of electronic technology, bringing together the precision of monolithic integration and the adaptability of discrete components. From telecommunications to aerospace, their applications are broad and impactful. The advantages they offer, including flexibility, reliability, and high assembly density, underscore their significance in the ever-advancing landscape of electronic systems.

Read More:

7404 Integrated Circuit (IC): Datasheet, Pinout, Pin Diagram, Truth Table

Photonic Integrated Circuit: Definition, Disadvantage, Fabrication, Application

What is Integrated Circuit Design?- How to Design?

7408 Integrated Circuit Datasheet: Pinout, Pin Diagram, Truth Table

How Is a Microprocessor Different From an Integrated Circuit

Small Outline Integrated Circuit - SOIC

Different Types of IC [Integrated Circuit]

IC 74192 UP/Down Counter Datasheet PDF, Circuit, Pin Diagram

IC 74190 Datasheet, Working, Features, Application

CD4017BE CMOS Counter: Circuit, Pinout and Uses [Datasheet PDF]

IC 7490 Decade Counter Datasheet: Features, Pinout, Circuit and Working

Extended Reading

FAQ

FAQ

-

Who invented hybrid integrated circuit?

The invention and development of hybrid integrated circuits (ICs) involve contributions from multiple researchers and engineers over time. In the 1960s, the hybrid IC technology gained prominence as researchers and engineers explored ways to integrate different technologies on a common substrate. Companies such as IBM, Fairchild Semiconductor, and Texas Instruments played significant roles in the early development and commercialization of hybrid ICs.

-

How does hybrid integrated circuit work?

A hybrid integrated circuit (IC) operates by integrating various electronic components, such as resistors, transistors, and sometimes complete semiconductor chips, onto a common substrate. The substrate serves as a foundation for circuit layout, interconnection, and metalization. Once assembled and encapsulated, the hybrid IC performs specific electrical tasks based on its design, such as signal amplification, modulation, or control functions.

-

How is a hybrid integrated circuit constructed?

A hybrid integrated circuit is constructed through a systematic process that begins with a 1/2-inch square ceramic wafer. Circuit patterns are initially laid down on the substrate, followed by the incorporation of resistive material, typically in the form of thin-film resistors. Metalization is then applied to enhance conductivity, and discrete components such as transistors and diodes are added. The entire assembly undergoes encapsulation for protection, and resistors are meticulously trimmed to achieve precise values.

-

What is the disadvantage of hybrid integrated circuits?

Hybrid integrated circuits (ICs) exhibit several disadvantages, including potentially larger size and weight, complex assembly processes leading to increased production costs, susceptibility to interference and crosstalk, limited integration density compared to monolithic ICs, environmental sensitivity, and testing challenges. Despite these drawbacks, hybrid ICs offer unique advantages in specific applications where customization, diverse component integration, and adaptability are prioritized over size and production simplicity.

Popular Blogs

-

![PCA9617ADPJ Datasheet | NXP Semiconductors]()

PCA9617ADPJ Datashee...

The PCA9617ADPJ is a signal buffer and repeater ...

-

![D882 Transistor Pinout, Equivalent, Uses and Datasheet]()

D882 Transistor Pino...

The D882 transistor is a commonly used NPN bipol...

-

![C1815 Transistor Datasheet, Pinout, Equivalent, Voltage, Circuit and Uses]()

C1815 Transistor Dat...

The C1815 is a general purpose NPN transistor us...

-

![C945 Transistor Datasheet, Pinout, Equivalent and Uses]()

C945 Transistor Data...

The C945 transistor is a small, low-power NPN bi...

.jpg)