Small Outline Package (SOP): Definition, Applications and Advantages

Update Time: May 31, 2023 Readership: 5860

Contents

Small Outline Packages (SOPs) have revolutionized the field of integrated circuits by providing a compact and versatile solution for the packaging of electronic components. In this article, we will explore the definition, applications and benefits of SOP packages. From smartphones to automotive systems, SOP packages have become ubiquitous in various industries due to their space-saving design and compatibility with surface mount technology. We believe this article will give you a more comprehensive understanding of SOP packages so that you can have more options when shopping for SOP packages.

What is SOP (Small Outline Package)?

SOP stands for Small Outline Package and is an integrated circuit (IC) package that provides a compact and thin form factor for electronic components. It is designed to be surface mounted on a printed circuit board (PCB), offering the advantages of space efficiency and ease of manufacturing. SOP packages are used in a wide range of electronic devices, including consumer electronics, telecommunications equipment, automotive systems and more. SOP designs include standardized dimensions and pin configurations, making them compatible with automated assembly processes. Therefore,SOP packages are well suited for miniaturization and high-density electronic applications.

Different Kinds of SOP

SOP-4:

SOP-4, also known as Small Outline Package-4, is an integrated circuit package that consists of four leads or pins. This type of SOP is commonly used for simple semiconductor devices or passive components like diodes and transistors. Its compact size and low pin count make it suitable for applications where space is limited.

SOP-5:

SOP-5, or Small Outline Package-5, is an integrated circuit package that contains five leads or pins. SOP-5 is often used for discrete components like voltage regulators, temperature sensors, or small analog circuits. It offers a compact form factor while providing basic functionality in applications where a minimal pin count is sufficient.

SOP-6:

SOP-6, or Small Outline Package-6, is an integrated circuit package that features six leads or pins. It is typically used for small-scale electronic components like small signal transistors or specialized ICs. SOP-6 provides a compact footprint and is well-suited for applications where a limited number of connections are required.

SOP-7:

SOP-7, or Small Outline Package-7, is another variant of the SOP package. It has seven pins, making it slightly smaller than SOP-8. SOP-7 packages are typically used for integrated circuits with fewer pin requirements. Due to its reduced pin count, SOP-7 is commonly found in simpler devices such as voltage regulators, audio amplifiers, and other low-pin count ICs.

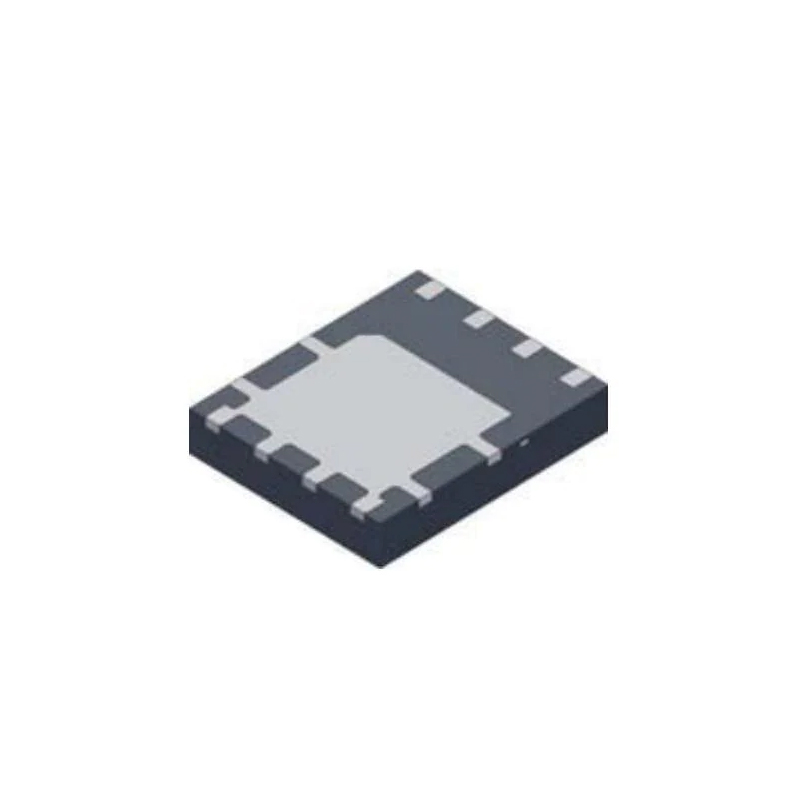

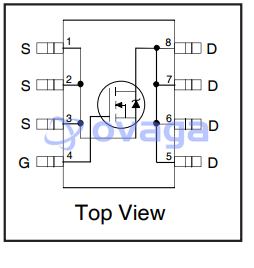

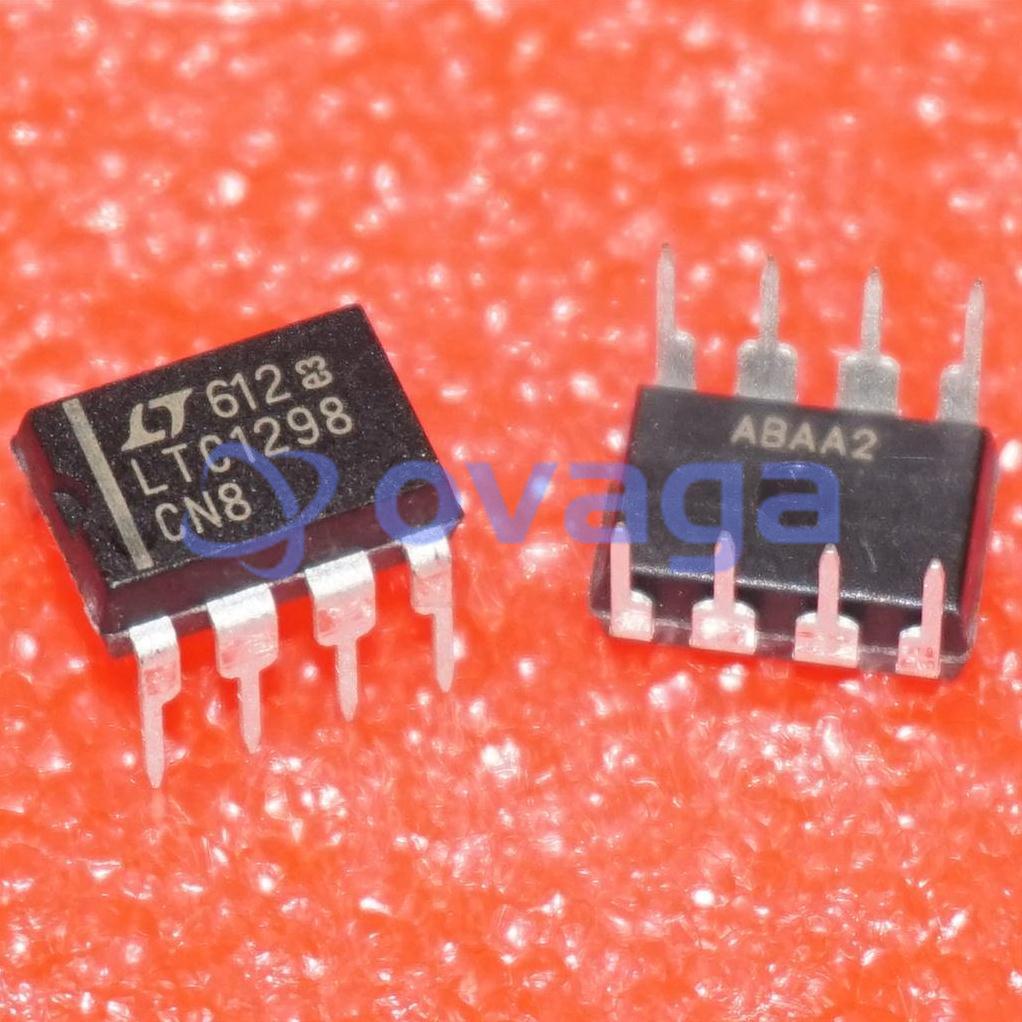

SOP-8:

SOP-8, also known as Small Outline Package-8, is a type of SOP package that consists of eight pins. It is commonly used for integrated circuits with moderate pin counts. The SOP-8 package features a compact size and a thin profile, making it suitable for space-constrained applications. It is widely used in various electronic devices such as power management ICs, microcontrollers, operational amplifiers, and other general-purpose ICs.

SOP-14:

SOP-14, or Small Outline Package-14, is an integrated circuit package that features 14 leads or pins. This type of SOP is commonly used for more complex semiconductor devices such as microcontrollers, memory chips, and operational amplifiers. The additional pins allow for increased functionality and connectivity.

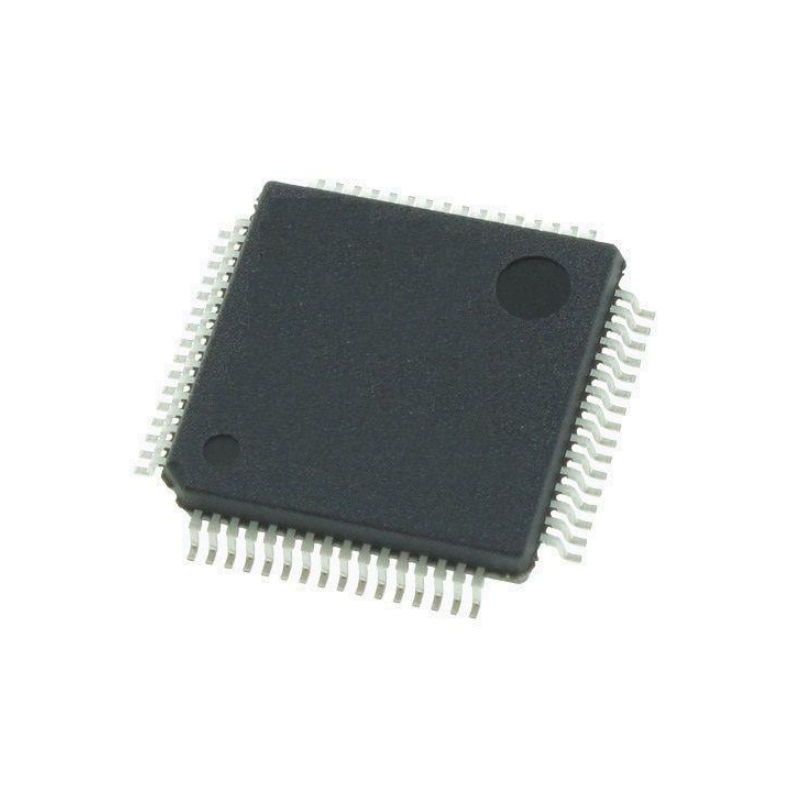

SOP-16:

SOP-16, or Small Outline Package-16, is a larger SOP package with sixteen pins. It provides a higher pin count compared to SOP-8, allowing for more complex integrated circuits. SOP-16 packages are commonly used in various applications, including microcontrollers, memory ICs, interface chips, and other integrated circuits requiring a larger number of connections. The increased pin count in SOP-16 enables more functionality and expanded capabilities in electronic systems.

SOP-20:

SOP-20, or Small Outline Package-20, is an integrated circuit package that consists of 20 leads or pins. It is commonly used for medium to high complexity integrated circuits, such as microprocessors, digital signal processors, or application-specific integrated circuits (ASICs). SOP-20 allows for a greater number of I/O connections, making it suitable for advanced electronic systems.

Overall, SOP packages come in various pin configurations to accommodate different integrated circuit requirements, ranging from simpler SOP-7 packages to larger and more feature-rich options like SOP-16.

SOP Size

Few examples of different sizes of SOP (Small Outline Package) packages:

| Package Type | Pin Count |

| SOP-8 | 8 |

| SOP-14 | 14 |

| SOP-16 | 16 |

| SOP-20 | 20 |

| SOP-28 | 28 |

| SOP-32 | 32 |

From the above table, we can see that the SOP package rule is that there are several pins on the SOP- followed by the corresponding number, the above only lists the individual SOP package types, you can use this rule to analogize.

Difference between SOP and SOIC

SOP (Small Outline Package) and SOIC are two common types of surface-mount packages used for integrated circuits. While there are similarities between them, there are also notable differences:

1. Pin Count: SOP packages generally have a lower pin count compared to SOIC packages. SOP packages often range from 8 to 32 pins, while SOIC packages typically have a higher pin count, starting from 8 pins and going up to 64 pins or more.

2. Size: SOIC packages are generally larger than SOP packages. SOIC packages have wider and longer dimensions to accommodate the higher pin count, while SOP packages are more compact and have a smaller footprint.

3. Lead Spacing: The lead spacing, or pitch, is another distinguishing factor. SOP packages typically have a smaller lead spacing, commonly 0.65 mm (25 mil) or 1.27 mm (50 mil), allowing for more closely spaced pins. SOIC packages, on the other hand, usually have a wider lead spacing of 1.27 mm (50 mil) or 2.54 mm (100 mil), making it easier to solder and handle.

4. Compatibility: SOP and SOIC packages have different footprints and pin configurations, which means they are not directly interchangeable. The PCB layout and footprint need to match the specific package type to ensure proper alignment and soldering.

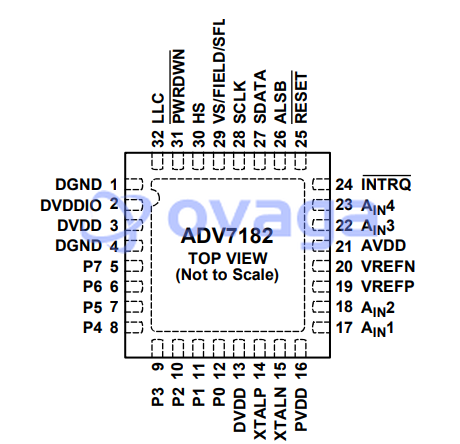

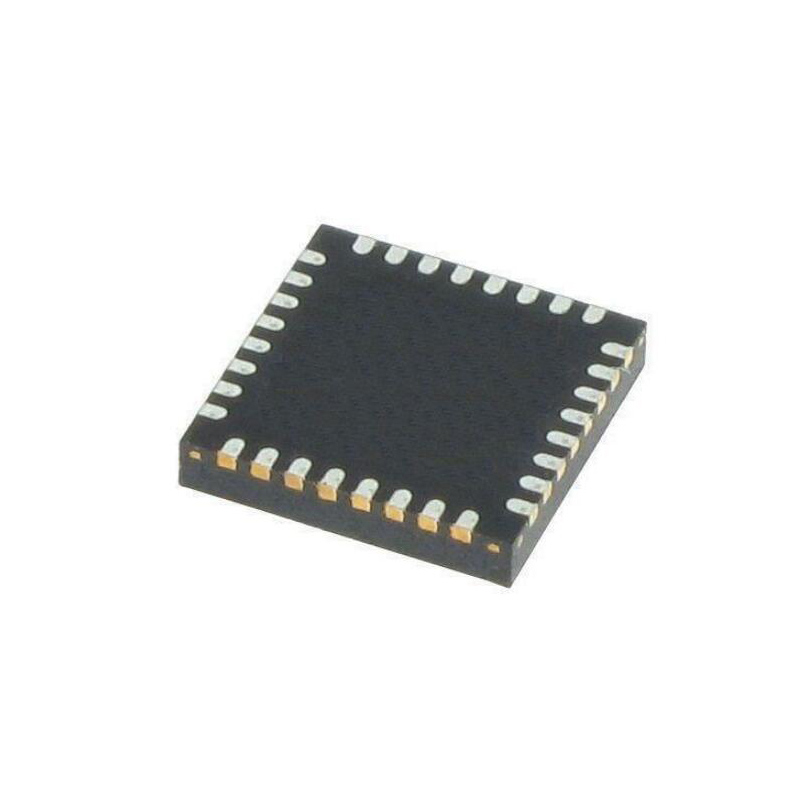

Structure of SOP

The structure of a SOP (Small Outline Package) typically includes the following elements:

1. Body: The body of the SOP package is a rectangular or square-shaped component that houses the integrated circuit. It provides a protective enclosure for the IC and serves as a base for mounting the pins.

2. Pins/Leads: SOP packages have a number of pins or leads that extend from the sides or bottom of the package. These pins provide the electrical connections between the integrated circuit and the external circuitry on the printed circuit board (PCB). The pin count can vary depending on the specific SOP package size and configuration.

3. Lead Frame: Inside the SOP package, there is a lead frame made of metal or alloy. The lead frame supports the pins and provides the electrical connections between the integrated circuit die and the external pins.

4. Die Attach Pad: The die attach pad is a flat area within the SOP package where the integrated circuit die is securely bonded or attached. The die attach pad helps to dissipate heat generated by the IC and provides mechanical stability.

5. Mold Compound: The body of the SOP package is typically encapsulated or molded using a protective material known as mold compound. The mold compound helps protect the integrated circuit from physical damage, moisture, and other environmental factors.

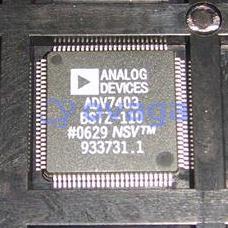

6. Marking: SOP packages often include markings or labels on the body to indicate important information such as the part number, manufacturer logo, date code, and other identification details. These markings help with identification and traceability of the IC.

Applications of SOP

SOP (Small Outline Package) finds extensive applications in various industries due to its compact size, compatibility with surface-mount technology, and versatility. Some common applications of SOP packages include:

1. Consumer Electronics: SOP packages are widely used in consumer electronic devices such as smartphones, tablets, digital cameras, portable media players, and gaming consoles. They are employed for microcontrollers, memory chips, power management ICs, audio/video processors, and other integrated circuits.

2. Telecommunications: SOP packages play a crucial role in telecommunications equipment, including routers, modems, switches, and network devices. They are used for communication processors, signal processors, interface chips, and other critical components.

3. Automotive Systems: In the automotive industry, SOP packages are employed in various applications, including engine control units (ECUs), infotainment systems, electronic control modules, and sensors. They provide reliable and compact solutions for automotive electronics.

4. Industrial Automation: SOP packages are utilized in industrial automation systems for control panels, motor drives, PLCs (Programmable Logic Controllers), and other automation components. They offer space-saving solutions and facilitate efficient operation.

5. Medical Devices: SOP packages are used in medical devices such as diagnostic equipment, patient monitors, imaging systems, and implantable devices. They provide compact and reliable solutions for critical medical electronics.

6. Aerospace and Defense: SOP packages are employed in aerospace and defense applications, including avionics, navigation systems, communication equipment, and radar systems. They are designed to withstand harsh environmental conditions and offer high-performance capabilities.

7. IoT (Internet of Things): SOP packages are widely used in IoT devices for connectivity modules, sensors, and edge computing applications. Their small form factor and compatibility with surface-mount technology make them suitable for IoT devices with size and power constraints.

SOP Pin Count Range

SOP (Small Outline Package) comes in a range of pin counts to accommodate various integrated circuit requirements. The pin count for SOP packages can vary depending on the specific variant and manufacturer.

At the lower end of the pin count spectrum, there are smaller SOP packages, such as SOP-4 to SOP-6, which typically have 4 to 6 pins. These compact packages are commonly used for simple integrated circuits that require a low pin count, such as basic voltage regulators or straightforward interface chips.

Moving up in pin count, SOP-8 is one of the most prevalent and widely used SOP package sizes. It consists of 8 pins and finds applications in a diverse range of integrated circuits, including microcontrollers, operational amplifiers, and power management ICs.

For more complex ICs requiring additional connectivity options, larger SOP packages are available. SOP-14 to SOP-16 packages feature 14 to 16 pins, offering a higher pin count compared to SOP-8. These packages are commonly used for memory ICs, interface chips, and advanced microcontrollers.

In situations where even more pins are needed, SOP-20 to SOP-32 packages come into play. These larger SOP packages provide 20 to 32 pins, enabling the integration of more advanced integrated circuits and systems. SOP-20 to SOP-32 packages are commonly used for complex microcontrollers, interface chips, and system-on-chip (SoC) designs.

SOP Advantages

SOP (Small Outline Package) offers several advantages that contribute to its widespread use in the electronics industry. Firstly, SOP packages are designed to be compact and thin, allowing for efficient use of space on printed circuit boards (PCBs). This compactness is particularly beneficial for miniaturized electronic devices where size constraints are critical, such as smartphones, wearables, and portable electronics.

Secondly, SOP packages are compatible with surface-mount technology (SMT), which simplifies the assembly and manufacturing processes. The standardized form factor and pin configuration of SOP packages enable automated assembly, reducing manufacturing costs and increasing production efficiency.

Another advantage of SOP packages is their excellent thermal dissipation capabilities. The compact size and often exposed pad on the bottom of the package facilitate efficient heat transfer from the integrated circuit to the PCB, helping to maintain optimal operating temperatures and improve overall system reliability.

Furthermore, SOP packages offer good electrical performance due to their short lead lengths, reduced parasitic effects, and optimized electrical characteristics. The close proximity of the pins in SOP packages reduces signal propagation delays and minimizes signal integrity issues, making them suitable for high-speed digital circuits.

Additionally, SOP packages often come with industry-standard footprints, ensuring compatibility across different manufacturers and facilitating easy integration into existing PCB designs. This standardization simplifies the design process and allows for interchangeability of components, offering flexibility to designers and manufacturers.

Selection of SOP

The selection of a SOP (Small Outline Package) depends on several factors that need to be considered to ensure compatibility and optimal performance for a specific integrated circuit (IC) and its intended application.

Firstly, the pin count requirement should be assessed. SOP packages are available in a range of pin counts, from smaller packages with fewer pins to larger packages with higher pin counts. The chosen SOP package should have a sufficient number of pins to accommodate the required connectivity and functionality of the IC.

Secondly, the physical dimensions and footprint of the SOP package should be taken into account. The available space on the PCB and any size constraints in the target application should guide the selection of an appropriately sized SOP package. It's important to ensure that the chosen SOP package can be easily mounted and soldered onto the PCB without any mechanical or spatial conflicts.

Additionally, thermal considerations are crucial. The power dissipation characteristics of the IC and the thermal properties of the SOP package need to be evaluated. If the IC generates significant heat, a SOP package with good thermal dissipation capabilities, such as a thermal pad or exposed pad, should be considered to facilitate efficient heat transfer and maintain safe operating temperatures.

Furthermore, the electrical requirements of the IC and the desired electrical performance should be taken into account. Factors such as signal integrity, high-speed requirements, and noise sensitivity should be considered when selecting a SOP package. It's important to ensure that the SOP package offers the necessary electrical characteristics to support the intended functionality and performance of the IC.

Lastly, compatibility and availability should be considered. The chosen SOP package should be compatible with the manufacturing processes and equipment available. It's also important to verify the availability and supply of the selected SOP package from reliable manufacturers.

Conclusion

In conclusion, SOP (Small Outline Package) is a versatile and widely used packaging option for integrated circuits. Its compact size, compatibility with surface-mount technology, and standardized form factor make it a preferred choice for various electronic applications. From consumer electronics to telecommunications, automotive systems to industrial automation, SOP packages offer efficient space utilization, ease of assembly, and reliable performance. As technology continues to advance and the demand for smaller and more powerful electronic devices grows, SOP packages will continue to play a crucial role in enabling innovative and efficient solutions for the ever-evolving electronics industry.

Read More:

Small Outline Integrated Circuit - SOIC

IC Package Types and Their Features

Small Outline Package (SOP): Definition, Applications and Advantages

Extended Reading

FAQ

FAQ

-

Are there environmentally-friendly versions of SOP packages available?

Yes, there are environmentally-friendly versions of SOP packages available. These packages may feature lead-free soldering options and comply with regulations such as Restriction of Hazardous Substances (RoHS) directives.

-

Are there different material options for the SOP package body?

Yes, SOP package bodies are typically made of mold compound, which is a protective material. However, for specific applications requiring enhanced thermal performance, some SOP packages may feature ceramic bodies instead of mold compound.

-

Can SOP packages be used for high-frequency applications?

Yes, SOP packages can be used for high-frequency applications. However, the electrical characteristics, such as lead inductance and parasitic capacitance, should be considered to ensure signal integrity and minimize signal degradation at higher frequencies.

Popular Blogs

-

Small Outline Packag...

SOP (Small Outline Package) is a type of integra...

-

CD4440 IC: Datasheet...

The CD4440 IC is a stereo audio power amplifier ...

-

Advantages and Disad...

Operational amplifiers, or op-amps, offer a host...

-

Dual Inline Package ...

Dual in-line package, also known as DIP package ...

Hot Products

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

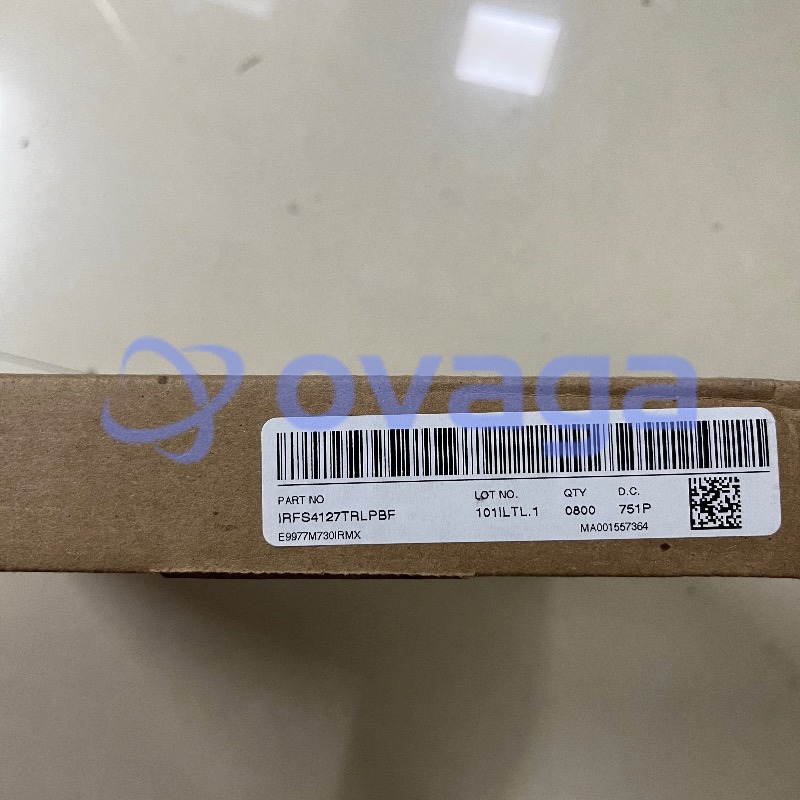

Infineon Technologies Corporation

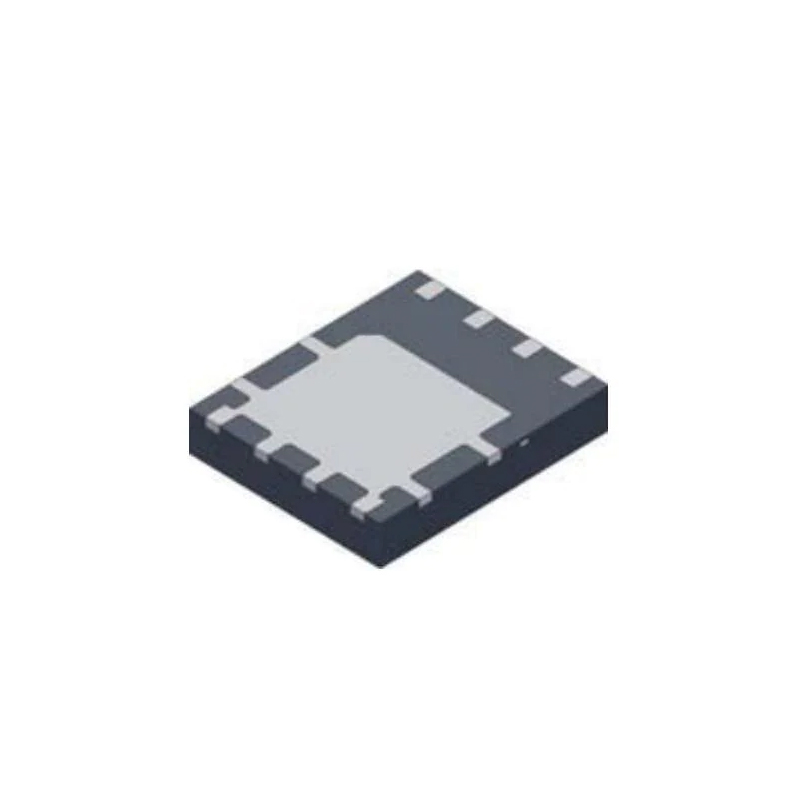

100V Single N-Channel HEXFET Power MOSFET in a PQF...

-

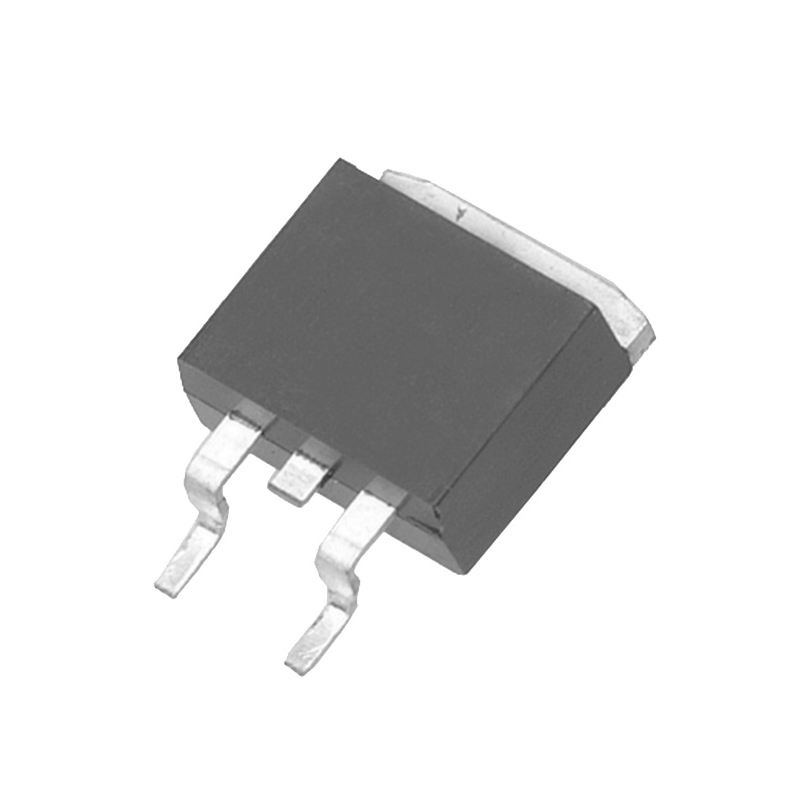

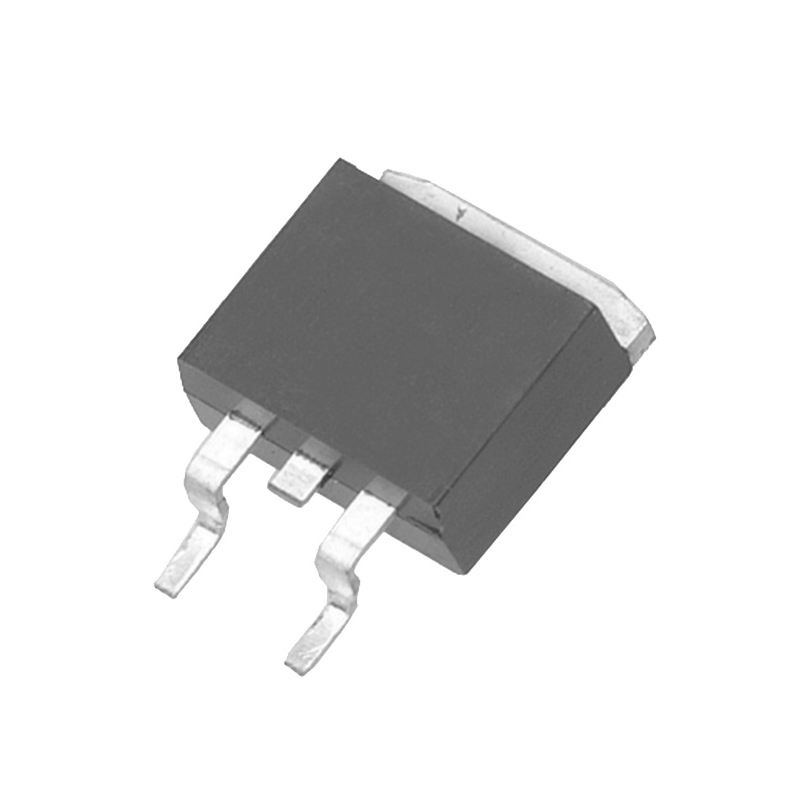

Infineon Technologies Corporation

100V Single N-Channel HEXFET Power MOSFET in a D2-...

-

Infineon Technologies Corporation

150V Single N-Channel HEXFET Power MOSFET in a 5mm...

-

Infineon Technologies Corporation

150V Single N-Channel HEXFET Power MOSFET in a D2-...

-

Infineon Technologies Corporation

200V Single N-Channel HEXFET Power MOSFET in a D2-...

-

-

Infineon Technologies Corporation

250V Single N-Channel HEXFET Power MOSFET PDP Swit...

-

-

-

-

-

Infineon Technologies Corporation

60V Single N-Channel HEXFET Power MOSFET in a PQFN...

-

Infineon Technologies Corporation

A 30V Single N-Channel HEXFET Power MOSFET in a Di...

-

-

-

-

-

-

-

-

-

-