In the age of intelligence, how does ST address the challenges of the industrial automation market?

With the advancement of technology, the current industrial environment has stepped into the era of intelligence, information technology, and automation. The various types of machines and equipment involved in industrial production, and completing manufacturing tasks, can also provide accurate data monitoring and analysis for people to better achieve production goals.

On September 8, 2020, Francesco Muggeri, Regional Vice President of Marketing and Applications, Power Discrete and Analog Devices Division, Asia Pacific, and Francesco Muggeri, Director of Industrial Product Marketing, Head of Automation Technology Innovation Center, Power Discrete and Analog Devices Division, Asia Pacific, STMicroelectronics, presented to OFD at the Industrial Automation Online Media Conference organized by STMicroelectronics. Allan LAGASCA presented to OFweek and many media outlets ST's development strategy for the industrial manufacturing market as well as its deep expertise in technology innovation.

Industrial market to meet the challenges of the automation era

According to Jerry Mu, automotive, industrial, personal electronics, communication devices/computers, and peripherals are the four strategic targets of ST, with a particular focus on the industrial market. As a leading brand in the industrial market, ST focuses on three key application areas: motor control, power and energy, and automation, and in addition to holding regular seminars, it has invested significant resources in building and establishing technology innovation centers.

Why is ST so interested in the industrial automation market? The industrial automation market itself is a market that requires a high level of technology, and both technology developers and application manufacturers are investing heavily in it. Data analysis shows that the industrial automation market will grow at a compound annual growth rate of 8% from 2019 to 2023. With the development of artificial intelligence technologies, embedded processing, robotics, and 5G infrastructure, the demand for the industrial automation market is accelerating even further.

ST's contribution and products

ST has been a member of the IO-Link Technology Alliance since the beginning of the active cooperation. ST introduces intelligent transceivers for device and main module applications. The device transceiver can be programmed with levels, diagnostic information, and filter timing according to application requirements. It includes Rx/Tx transmitting with COM1, COM2, and COM3 support, DC-DC power management, and complete power reverse protection. The transceiver solution for master module applications is based on a single port solution in an ultra-small QFN package. It offers the same flexibility as the device solution. Thanks to the advanced QFN package and our BCDVI mixed-signal technology, ST offers a cost-competitive IO-Link system solution. In addition to transceiver solutions, ST also offers complete system solutions to support device and main module applications.

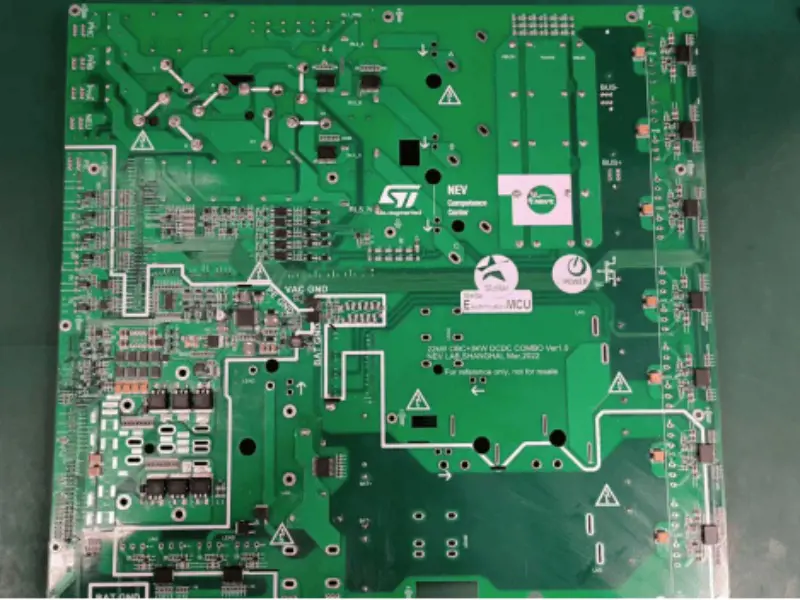

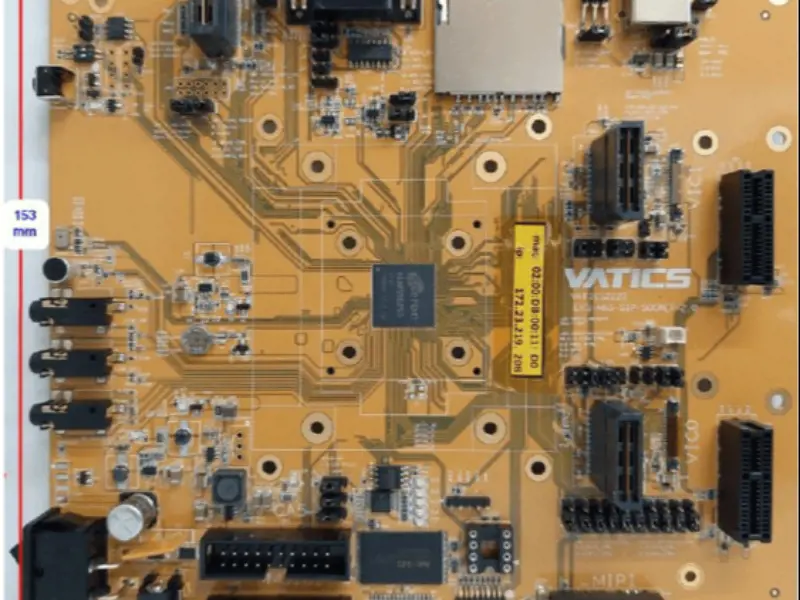

ST has a wide range of technologies and devices for factory automation systems. Complete system solutions are supported by development tools, evaluation boards, and dedicated user support centers. ST is strong in industrial automation and process control and is committed to long service life and the development of high-end technologies.

IO-Link Association / (IO-Link Standard)

IO-Link is the new communication interface for intelligent communication between sensors and actuators. Typical intelligent actuators and sensors include unidirectional solenoid valves and optical, capacitive, or inductive sensors. Advanced IO-Link is the open, integrated interface for automation environments. This allows integration with every fieldbus system. Sensors and actuators are connected in a point-to-point fashion using economical standard cables for the last 1 m of connection.

ST's automation solutions help revolutionize the market

According to Mujerik, the automation market can be divided into two main categories: factory automation and home, building, and city automation. Factory automation is closely related to automation systems and industrial robots, while home, building, and city automation is closer to personal/home safety and transportation.

To this end, ST has introduced several products and solutions, one for condition monitoring and predictive maintenance. Predictive maintenance is very important in the era of Industry 4.0, as it can anticipate potential failures or production line shutdowns in order to reduce the rate of sudden failures (e.g., sudden production line shutdowns) by 70%, allowing downtime to be reduced by 50%, resulting in cost savings of 30% for early fault detection and further reductions in regular maintenance costs.

According to Mujerik, the STEVAL-STWINKT1 is a first-class industrial-grade sensor for ultrasonic detection and analysis of mechanical vibrations. It has not only the detection functions of a sensor but also the data processing and analysis capabilities to safely transmit and send the data after it has been collected. In addition, the modules/nodes of the STEVAL-STWINKT1 offer ultra-low power consumption, which significantly increases the battery life. The product also features BLE Bluetooth module connectivity and sensor extension support, allowing multiple algorithms to run on the STM32L4+.

Mu Jie Li also presented two case demonstrations of typical applications for industrial motor monitoring and BLE-KNX intelligent lighting control with its own mobile application. According to the introduction, the complete ecosystem based on STM32 for AI provides industrial microcontroller solutions with excellent control and computing power for smart industrial scenarios. Control software libraries, etc.

For factory automation, the importance of communication connectivity is undeniable, and whether it is establishing wired and wireless communication, communication between devices and the main system, or even Apple and Android devices in a home automation system, ST has a solution for it. Another advantage of KNX is the reduction of energy consumption through the introduction of intelligent controls that enable HVAC, lighting, and ventilation systems to be intelligent and automated, such as automatically closing roller shutters when shading is required and automatically turning off fans in ventilation systems when rooms are empty, bringing many benefits to individuals, families, offices and other energy users. The benefits.