What is Energy Harvesting?

Update Time: Apr 07, 2023 Readership: 2828

Contents

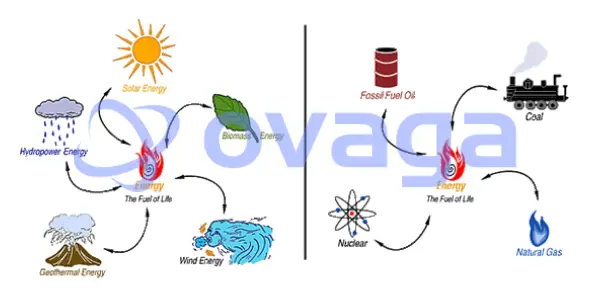

Nowadays, energy harvesting has become an innovative and increasingly important field focused on capturing the full spectrum of environmental energy and converting it into usable electricity. With increasing global demand for energy and concerns about the environmental impact of traditional energy production methods, energy harvesting shows the way to meet our energy needs while providing a sustainable option to reduce our dependence on fossil fuels.

Definition of Energy Harvesting

Energy harvesting, also known as energy scavenging or power harvesting, is the process of capturing and converting environmental energy from various sources into usable electrical energy. With increasing demand for energy and concerns about the environmental impact of traditional energy production methods, energy harvesting has emerged as the best option for meeting energy needs while providing a sustainable way forward to reduce our dependence on fossil fuels.

The significance of Energy Harvesting

Energy harvesting is of great importance in terms of sustainable energy, environmental protection and reducing dependence on fossil fuels. As a method of capturing environmental energy from various sources and converting it into usable electricity, it addresses several key aspects related to global energy issues.

Sustainable Energy: Energy harvesting technologies are designed to harness renewable and often inexhaustible sources of energy such as solar, wind and thermal energy. By harnessing these resources, energy harvesting develops sustainable energy systems; and helps meet the growing global energy demand without wasting limited resources.

Environmental Protection: Traditional methods of energy production, based primarily on fossil fuels, can be severely detrimental to the environment, including air pollution, greenhouse gas emissions and species degradation. Energy harvesting offers an environmentally friendly alternative, as it typically produces little to no harmful emissions or waste products. By employing energy harvesting technologies, we can significantly reduce the environmental impact of energy consumption.

Reduce dependence on fossil fuels: The global economy and energy infrastructure have long been dependent on fossil fuels. However, these resources are finite, and their extraction and utilization contribute to climate change and other environmental problems. Energy harvesting offers a way to diversify our energy sources and reduce our dependence on fossil fuels. By integrating energy harvesting technologies into our energy systems, we can create more resilient and sustainable energy solutions.

Decentralization and Energy Access: Energy harvesting technologies can be implemented at a variety of scales, from small portable devices to large-scale installations. This versatility allows for decentralized energy production, which can improve energy access in remote or off-grid areas and reduce the need for extensive energy transmission infrastructure.

In short, the significance of energy harvesting lies in its potential to contribute to a more sustainable, environmentally friendly and diverse energy future. By advancing and adopting energy harvesting technologies, we can work to address pressing global energy and environmental challenges and ultimately support the transition to a cleaner and more sustainable world.

The basic principles of Energy Harvesting

The basic principles of energy harvesting involve capturing environmental energy, converting it into electrical energy using appropriate sensors, conditioning and storing the energy, and finally using it to power various devices or systems. The following steps are detailed:

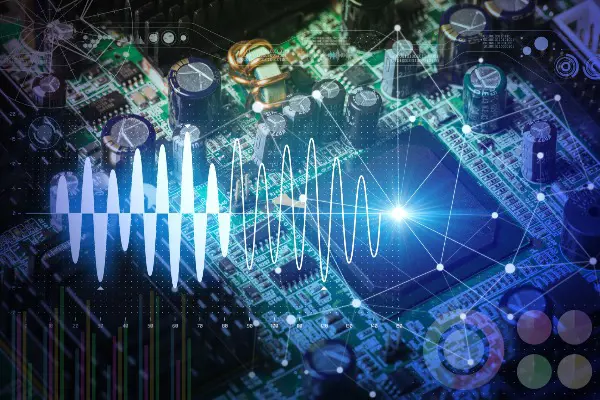

Capturing environmental energy: Environmental energy exists in various forms such as solar radiation, wind, temperature gradients, vibrations, and even radio frequency signals. The first step in energy harvesting is to use a suitable sensor or energy harvesting device to capture this energy.

Energy Conversion: Once the environmental energy has been captured, it must be converted to electrical energy. This conversion process usually involves a transducer, which is a device that converts one form of energy into another. The choice of transducer depends on the type of ambient energy being captured. Some common types of transducers include photovoltaic cells (for solar energy), piezoelectric materials (for mechanical energy), thermoelectric generators (for thermal energy), and electromagnetic harvesters (for vibration and RF energy).

Conditioning and Storage: After conversion, the resulting electrical energy usually comes in the form of alternating current (AC) or direct current (DC) with varying voltage levels. In order to make this energy available, it must be conditioned, which involves regulating the voltage, current, and frequency. This step usually involves power management circuits and devices such as voltage regulators, rectifiers and charge controllers. Once regulated, the electrical energy can be used directly by electronic devices or stored for later use in an energy storage system, such as a battery, capacitor or supercapacitor.

Utilization: The final step is to use the collected electrical energy to power devices, systems, or even the power grid. This step is critical for integrating energy harvesting technologies into a variety of applications, such as powering sensors, wireless communication devices, or supplementing the energy supply of a larger system.

By harnessing energy from the environment, energy harvesting technologies provide sustainable and environmentally friendly solutions to meet our energy needs.

Challenges and Limitations

Intermittency and variability: Many ambient energy sources, such as solar and wind, are inherently intermittent and variable, making it difficult to guarantee a consistent and reliable energy supply. This issue can be partially mitigated through energy storage solutions or hybrid systems that combine multiple energy harvesting technologies, but these solutions can add complexity and cost to the overall system.

Efficiency and conversion losses: Energy harvesting technologies often have lower conversion efficiencies compared to traditional energy generation methods. These conversion losses can limit the overall effectiveness of the energy harvesting system and may require further research and development to improve efficiency.

Cost and return on investment: While energy harvesting technologies have the potential to reduce long-term energy costs and environmental impact, their initial installation and maintenance costs can be high. This can make it difficult for some applications to justify the investment, particularly when compared to the low cost of some traditional energy sources.

Conclusion

In conclusion, energy harvesting is a promising and innovative approach to meeting the world's growing energy needs while addressing environmental concerns and reducing dependence on fossil fuels. The significance of energy harvesting lies in its potential to contribute to a sustainable, environmentally friendly and diverse energy future. By capturing environmental energy from a variety of sources and converting it into usable electricity, energy harvesting technology offers a scalable and cost-effective solution for generating energy.

While energy harvesting technologies face a number of challenges, today's research and development efforts are improving efficiency, reducing costs, and overcoming barriers. As energy harvesting technologies continue to advance, their applications are expanding in multiple sectors, including transportation, agriculture, infrastructure and consumer electronics. By applying energy harvesting solutions wisely, we can create a cleaner, more sustainable and resilient energy future that benefits both society and the environment.

Extended Reading

FAQ

FAQ

-

How does photovoltaic energy harvesting work?

Photovoltaic energy harvesting involves the use of photovoltaic cells to convert sunlight into electrical energy.

-

What are the different types of energy harvesting technologies?

Some of the common types of energy harvesting technologies include photovoltaic cells, piezoelectric materials, thermoelectric generators, and electromagnetic harvesters.

-

What are the benefits of energy harvesting?

Energy harvesting offers several benefits, including sustainable energy production, environmental conservation, reducing reliance on fossil fuels, and decentralized energy generation.

Popular Blogs

-

What is Integrated C...

IC design, short for integrated circuit design, ...

-

Types and Applicatio...

As the world continues to search for sustainable...

-

What is an Analog In...

An analog integrated circuit mainly refers to an...

-

What Can ChatGPT Bri...

ChatGPT's popularity continues, and although it ...

Hot Products

-

-

-

Infineon Technologies Corporation

INFINEON - IFX9201SGAUMA1 - MOTOR CONTROLLER, HALF...

-

Infineon Technologies Corporation

solar inverters as well as SMPS and uninterruptibl...

-

Microchip Technology, Inc

32-bit Microcontrollers - MCU PIC32MK, 1MB Flash, ...

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Infineon Technologies Corporation

EV charging: Off-board charging, where users can ...

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-