What is the Resistor Block?

Update Time: Jun 02, 2023 Readership: 2913

Contents

The world of electronics is driven by the precise control of electrical currents and voltage levels. One crucial component that enables this control is the resistor block. Resistor blocks are versatile and compact arrangements of interconnected resistors, serving as fundamental building blocks in countless electronic applications. In this article, we will delve into the intricacies of resistor blocks, exploring their construction, applications, advantages, and considerations for designing with them. Join us on this journey to unravel the mysteries of the resistor block and understand its pivotal role in modern electronics.

What is a Resistor Block?

A resistor block is an electronic component that consists of multiple resistors integrated into a single package. These resistors are interconnected in various configurations, such as series or parallel, to provide specific resistance values and power ratings. Resistor blocks are widely used in electronic circuits to control current flow and voltage levels, allowing for precise regulation and adjustment of electrical parameters. They offer convenience, compactness, and cost-effectiveness compared to using individual resistors. Resistor blocks find applications in various industries, including telecommunications, automotive, consumer electronics, and industrial equipment.

Resistor Block Function

The primary function of a resistor block is to control the flow of electric current and regulate voltage levels in electronic circuits. It achieves this by providing a specific resistance value within the circuit. Here are the key functions and roles of resistor blocks:

1. Current Limiting: Resistor blocks are often used to limit the amount of current flowing through a circuit. By selecting an appropriate resistance value, the block can restrict the current to a desired level, preventing damage to sensitive components or ensuring safe operation.

2. Voltage Division: Resistor blocks facilitate voltage division in circuits. By incorporating resistors with specific values, they can divide the input voltage into desired proportions, allowing for precise voltage levels at different points within the circuit.

3. Voltage Dropping: In some cases, resistor blocks are employed to drop voltage across a specific component or section of the circuit. By selecting an appropriate resistance, the block dissipates a portion of the voltage, thereby reducing it to the desired level.

4. Signal Conditioning: Resistor blocks are used for signal conditioning, where they modify and adjust the characteristics of electrical signals. By introducing specific resistances, they can attenuate, amplify, or filter signals, ensuring optimal signal quality and compatibility with other circuit elements.

5. Temperature Sensing and Compensation: Some resistor blocks include resistors with temperature-sensitive properties, such as temperature coefficient of resistance (TCR). These blocks are utilized for temperature sensing and compensation, enabling circuits to adjust their behavior in response to temperature changes.

6. Current Sensing and Shunting: Resistor blocks can be employed as current sensing elements in circuits. By measuring the voltage drop across a known resistance, they allow for the calculation of current flow. They can also serve as shunt resistors, diverting a portion of the current away from sensitive components for measurement or protection purposes.

Overall, resistor blocks play a vital role in maintaining desired electrical characteristics, ensuring proper functioning, and protecting electronic components within various applications. They provide control, precision, and flexibility in circuit design, allowing engineers to achieve specific performance requirements and meet application demands.

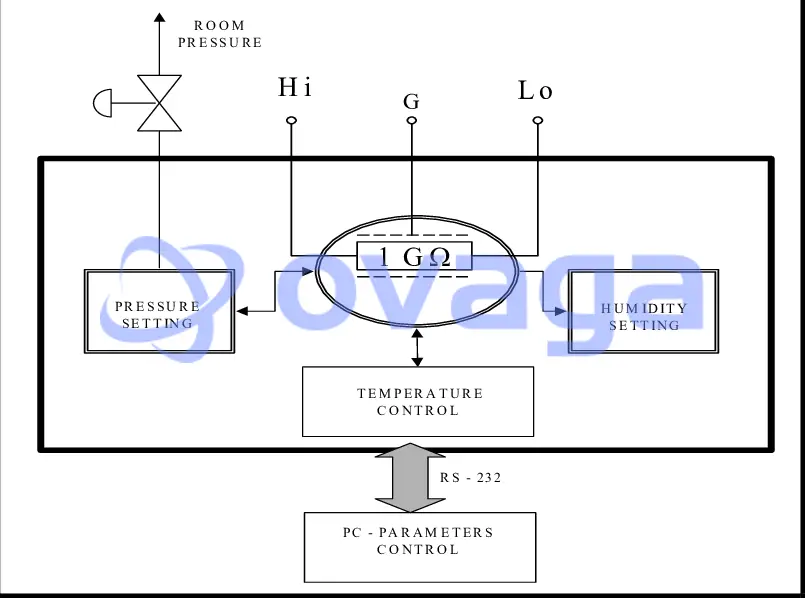

Resistor Block Diagram

Here are the example of Block Diagram of the 1GΩ Resistor:

In a resistor block diagram, you would typically see multiple resistors connected together within a single package. The resistors are interconnected in various configurations depending on the specific design requirements. The diagram may illustrate the connections using lines or symbols representing the resistors and their interconnections.

For example, a resistor block diagram might show resistors arranged in series, where the output of one resistor connects to the input of the next. Alternatively, the resistors could be configured in parallel, with their terminals connected together at both ends. It is also possible to have a combination of series and parallel connections within a resistor block.

The diagram may also include markings or labels indicating the resistance values of each individual resistor or the total resistance of the block. In some cases, there may be additional components or connections, such as terminals for external connections or temperature-compensating elements.

Resistor Block Applications

Resistor blocks find a wide range of applications in various electronic systems and circuits. Here are some common applications where resistor blocks are utilized:

Power Supplies: Resistor blocks are frequently employed in power supply circuits to regulate and stabilize voltage levels. They help set the desired voltage output by providing voltage division and current limiting.

Amplifiers: Resistor blocks are used in amplifier circuits to control gain and provide biasing. They assist in setting the proper voltage and current levels for optimal amplification.

Voltage Dividers: Resistor blocks are utilized as voltage dividers to split and adjust voltage levels in circuits. They allow for precise control and calibration of signals in applications such as measurement devices and sensor interfaces.

Signal Conditioning: Resistor blocks play a crucial role in signal conditioning circuits, where they modify and shape input signals to match the requirements of subsequent circuitry. They can attenuate or amplify signals, provide impedance matching, or filter out unwanted frequencies.

Feedback Networks: Resistor blocks are commonly used in feedback networks of operational amplifiers (op-amps) and other feedback-based systems. They determine the gain, stability, and frequency response characteristics of the circuit.

Current Sensing: Resistor blocks are utilized as current sensing elements in circuits where the measurement or monitoring of current flow is required. By measuring the voltage drop across a known resistance, they enable accurate current measurements.

Temperature Compensation: Resistor blocks with temperature-sensitive resistors, such as thermistors, are employed for temperature sensing and compensation. They help maintain stability and compensate for changes in circuit behavior due to temperature variations.

Attenuators: Resistor blocks can act as attenuators, reducing the amplitude of signals. They are used in audio systems, communication systems, and RF circuits to adjust signal levels according to specific requirements.

Calibration and Testing: Resistor blocks are essential in calibration and testing procedures, where precise resistance values are needed to verify and calibrate the performance of electronic instruments and systems.

Circuit Protection: Resistor blocks can serve as shunt resistors, diverting excess current away from sensitive components to protect them from damage caused by overcurrent or short circuits.

Advantages and Disadvantages

Advantages of Resistor Blocks:

Resistor blocks offer several advantages in electronic circuit design and implementation. Firstly, their compact design allows for space-saving integration, particularly in applications with limited board space or size constraints. This can contribute to overall system miniaturization and improved packaging density. Additionally, resistor blocks provide convenience by combining multiple resistors into a single package, simplifying the assembly process and reducing the number of individual components required. This streamlines manufacturing and enhances overall production efficiency. Resistor blocks also offer cost-effectiveness compared to using multiple individual resistors, making them a budget-friendly option for circuit designers. Moreover, they can provide improved thermal management as heat generated by the resistors is concentrated in a confined area, allowing for better heat dissipation and reducing the impact on neighboring components. This can result in enhanced reliability and longevity of the overall circuit.

Disadvantages of Resistor Blocks:

Despite their many advantages, resistor blocks also have certain limitations and disadvantages. One notable limitation is the restricted resistance range available within a single resistor block. The available resistance values are predetermined by the specific combination and configuration of resistors within the block, which may not cover the entire range required for certain applications. Another disadvantage is the potential for higher tolerances compared to individual resistors. Due to manufacturing processes and the combination of multiple resistors, the overall tolerance of a resistor block may be slightly higher than that of individual resistors. This can introduce a margin of error in certain precision applications. Additionally, resistor blocks may not be suitable for applications where fine-tuning or adjustments of individual resistors are necessary. In such cases, using individual resistors allows for more precise customization. Lastly, in some cases, resistor blocks may have limited power handling capabilities compared to larger, standalone resistors. Higher power dissipation requirements may necessitate the use of separate, higher-rated resistors.

Design Considerations

When selecting and designing with resistor blocks, it is crucial to consider several key factors. First, ensure that the resistor block offers resistance values suitable for your application's requirements. Additionally, check that the power ratings of the resistor block align with the expected power dissipation in your circuit. Pay attention to tolerance levels to ensure the desired precision is achieved. Explore options for customization and adjustability of the resistor block configuration to meet specific design needs. Take measures to minimize errors and ensure reliability by optimizing layout, heat dissipation, and connections. Consider the environmental conditions in which the resistor block will operate and choose one that can withstand those conditions. Lastly, consult documentation and specifications provided by manufacturers to make informed decisions based on accurate information. By considering these design considerations, you can select and design with resistor blocks effectively for your electronic circuits.

Resistor Block Manufacturing

Resistor block manufacturing begins with the fabrication of individual resistors. The resistors are created by depositing or applying a resistive material onto a substrate, such as a ceramic or fiberglass board. The specific resistive material used depends on the desired characteristics of the resistor, such as carbon composition, metal film, or thick film.

Once the resistors are fabricated, they undergo trimming and testing processes. Trimming involves adjusting the resistance values of the individual resistors to meet precise specifications. This can be achieved through laser trimming or other precision methods. Each resistor is then thoroughly tested to ensure it meets the desired resistance values, tolerance levels, and performance requirements.

After the individual resistors are prepared, they are integrated into a single package to form the resistor block. The resistors are interconnected in series, parallel, or a combination of both configurations to achieve the desired resistance values and configurations. The connection can be established through wire bonding or soldering to internal leads or terminals within the package.

To provide mechanical protection and insulation, the resistor block is encapsulated using materials like epoxy or other suitable compounds. This encapsulation process ensures the stability, durability, and protection of the integrated resistors within the block.

In terms of industry standards and regulations, resistor block manufacturing is guided by various quality control practices and compliance with standards such as the International Electrotechnical Commission (IEC) 60115 series. These standards define parameters such as resistance values, power ratings, tolerance levels, and temperature coefficients to ensure consistency and interoperability of resistor blocks across different manufacturers and applications.

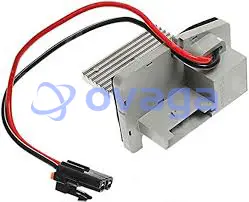

Resistor Block for Car Aircon

A resistor block, commonly referred to as a blower motor resistor, is a crucial component in the air conditioning system of a car. It is responsible for controlling the speed of the blower motor that drives the air circulation within the vehicle's cabin. Here's how the resistor block functions in a car's air conditioning system:

The blower motor resistor is typically located near the blower motor assembly, often behind the dashboard or in the engine compartment. It consists of multiple resistors, usually arranged in a series or parallel configuration, and is connected to the car's electrical system.

When the air conditioning system is activated, the blower motor resistor regulates the amount of electrical current flowing to the blower motor. By altering the current, the resistor block controls the speed of the blower motor, which, in turn, affects the air volume and temperature within the cabin.

The resistor block achieves speed control by utilizing resistors with different resistance values. Each resistance value corresponds to a specific fan speed setting. When the driver adjusts the fan speed control on the air conditioning panel, the resistor block selects the appropriate resistance to deliver the desired fan speed.

This speed control mechanism allows the car occupants to adjust the airflow and maintain a comfortable interior temperature based on their preferences. By providing various speed options, the resistor block ensures efficient air distribution and prevents the blower motor from operating at full speed all the time, which could lead to excessive noise, increased energy consumption, and unnecessary wear on the motor.

It's worth noting that in some modern vehicles, electronic control modules (ECMs) or climate control systems may replace traditional resistor blocks. These advanced systems utilize electronic components and algorithms to regulate fan speed. However, the core function of controlling the blower motor's speed remains the same.

In summary, the resistor block in a car's air conditioning system plays a crucial role in regulating the speed of the blower motor. By providing variable fan speeds, it enables the driver and passengers to adjust the airflow and maintain a comfortable environment inside the vehicle.

Conclusion

In conclusion, resistor blocks are essential components in various electronic applications, including car air conditioning systems. Their role in controlling the speed of the blower motor ensures efficient airflow and optimal comfort within the vehicle's cabin. By adjusting the resistance values and controlling the electrical current, resistor blocks allow for customizable fan speed settings. This compact and cost-effective solution simplifies the assembly process and enhances overall production efficiency. While newer technologies may be emerging, the fundamental purpose and importance of resistor blocks in regulating fan speed remain vital. As electronic systems continue to advance, resistor blocks will continue to play a crucial role in delivering reliable and adjustable air conditioning performance.

Extended Reading

FAQ

FAQ

-

Are resistor blocks suitable for precise resistance requirements in electronic circuits?

While resistor blocks offer convenience and versatility, they may have slightly higher tolerances compared to individual resistors due to the combination of multiple resistors. Therefore, for applications that require precise resistance values or fine-tuning, using individual resistors may be more appropriate. However, resistor blocks are still widely used in many applications where the tolerance levels are within an acceptable range.

-

How does a resistor block control the speed of a blower motor in a car's air conditioning system?

A resistor block regulates the speed of the blower motor by altering the electrical current flowing to it. It utilizes resistors with different resistance values, each corresponding to a specific fan speed setting. By selecting the appropriate resistance, the resistor block controls the current and, subsequently, the speed of the blower motor.

Popular Blogs

-

NTC 103 Thermistor: ...

Thermistor 103 is a type of NTC thermistor, with...

-

Define 2200(2.2k) Oh...

A 2200-ohm resistor is an electrical component t...

-

What is a 10k Resist...

The 10k resistor is a type of resistor, and we u...

-

Safeguarding Electri...

A neutral earthing resistor (NGR) is an electric...