ST supports a wide range of motor control in automation and industry.

Preface

Motor drives are a key feature of the automation industry market, and ST, which has been working in the field of motor control for many years, has a wide range of motor-specific hardware and software solutions. , ST MC (Motor Control) ecosystem contains total solutions such as evaluation boards, firmware (FW) libraries, and related materials to meet the needs of various applications.

Now available in the ST MC ecosystem is a new firmware library for permanent magnet synchronous motor (PMSM) control called STM32 PMSM FOC SDK v4.0. These tools are the result of ST's deep knowledge and system experience accumulated over many years in the field of CNC and power system solutions, and they help to shorten customer product development cycles and speed up the evaluation of ST's products. Indeed, ST supports a wide range of motor controls in automation and industry thanks to an innovative product portfolio that includes power transistors, intelligent power modules, motor driver chips, and the latest microcontrollers.

The PMSM FOC SDK features and dedicated algorithms enhance the practical value of ST's industrial motor drive products for evaluation.

To achieve this, hardware and firmware solutions must work in tandem. In addition, a number of different dedicated algorithms have been added to the very familiar three-phase brushless motor vector control technology (FOC) in order to achieve the highest motor control performance.

1 Automation and industrial motor control

ST has been developing vector control technology for many years, releasing the first 3-phase motor control firmware library supporting STM32 microcontrollers and STM32 motor control development boards in 2009. Since then, the solution has been continually refined with the addition of several new features:

- Sensorless permanent magnet motor control (two complementary algorithms, counter-electromotive force state estimator and high-frequency injection)

- Fully configurable firmware library supporting the full STM32F product range (F0, F1, F2, F3, F4), ST's power level products (e.g., SLLIMM smart power modules), or discrete solutions (power MOSFETs, IGBTs, gate drivers)

- Configuration of the firmware library via PC software (ST MC Workbench), helping the user to set up the system and communicate in real time between the PC and firmware

- Dual drive" motor control with one microcontroller driving two motors simultaneously

- Other functions such as flux weakening, MTPA (maximum torque to current ratio), and feed-forward current regulation for internal magnet motors

Firmware and hardware tools (control stage + power stage or total solution) to help users start prototyping quickly

2 Permanent magnet synchronous motor control ecosystem

STM32 FOC SDK V4.0 New Features

STM32 FOC SDK V4.0, the latest version of the firmware library for 2014, features architectural improvements that focus on the ease of use of the firmware. Enhanced ease of use helps users to speed up product design and shorten development cycles, two factors that are key to the success of electronics companies. To improve the ease of use of software development tools, from source code to GUI software for PCs, ST's motor control ecosystem has added many new features and comes with a set of development materials that include technical documentation, FAQs, presentations, software examples, use cases, tutorials, and videos. All materials are included in the standard software and firmware packages, which can be downloaded from the ST website, while requests for full C source code must be made to your local ST representative.

The STM32 FOC SDK V4.0 ecosystem includes the two main tools needed for fast and efficient design: the firmware library and the PC GUI software.

From the cost-effective 48Mhz Cortex-M0 STM32F030x to the STM32F30x with integrated analog IP modules to the state-of-the-art 180Mhz Cortex-M4 STM32F4 with floating-point instruction support, the renowned STM32 Vector Control firmware library supports the entire STM32 F product range. From small motors for medical applications to large servo motors for factory automation or power traction, the STM32 covers a wide range of motor control applications. Unlike other brands of motor control solutions, the STM32 FOC firmware library takes an object-oriented approach, which is why ST's firmware library supports different families of microcontrollers.

In addition to retaining the benefits of the previous version's well-structured software abstraction layer, version V4.0 simplifies Workspaces and reduces the number of items to be configured each time. In addition, the IDE development environment supported by the firmware library, which used to be only IAR Embedded Workbench, now also supports the KEIL Microvision integrated development environment.

The Motor Control Application Programming Interface (API), which was the flagship technology in the previous version, has been added to the API in the new version. In addition, a set of software examples has been added to the new version of the package. Users can implement typical use cases using functions exported from the motor control API and use them in the final application design, for example.

- Setting a speed reference value based on an analog input voltage;

- Proportional relationship of the output PWM signal to the speed measurement;

- real-time modification of parameters such as controller bandwidth;

- real-time modification of the speed sensor and position sensor parameters of the control loop

All the code required to implement this functionality is included in the software examples, which can be used as a basis for creating more complex projects or as a reference guide to understanding the logic behind the API itself. The motor control library doubles as a black box on how to issue commands to the motor, e.g., to start, stop or decelerate, and can also be used to receive motor feedback signals, e.g., measurements of speed, torque, or power. The firmware library also enables customers to focus on top-level application development and to design differentiated solutions using specific strategic knowledge.

3 MC SDK 4.0 user interface

In version 4.0, the firmware user interface has two communication channels. If the control board is equipped with an LCD LCD screen, a light (small code size) LCD GUI can be implemented. The short version of the LCD enables more flexibility to customize the GUI and add more user firmware interaction features. If the control board does not have an LCD screen, a real-time communication channel can be established between the firmware and the PC via USART. v4.0 can also establish a fast unidirectional communication channel, allowing the firmware to send data to the PC continuously at the maximum rate, without including control bytes for monitoring rapidly changing variables.

Other new features of Workbench:

- A new Imposed Current and Acceleration GUI in the sensorless start-up setup window, bringing the benefit of visual parameter descriptions to the user

- Workbench project configurations distributed as a bundle with the tool have been enriched to cover various reference design boards

- The link between Workbench and the technical documentation has been enhanced so that after entering a new project in the program menu, the user is directed to the technical documentation: Quick Start, User Manual, Developer Manual, and API Reference Manual

- In addition, Workbench, which has fully supported digital PFC boards since the last version, is now also able to set the power stage AC input range, handle implemented safety functions such as overcurrent and overvoltage, and allow the user to set suitable thresholds at the driver management level

Zero speed control using high-frequency injection

The improvements in the new firmware are not limited to experience and ease of use. Version 4.0 includes a new sensorless control algorithm as well as the "state of the art" BEMF state estimator from the previous version; the new sensorless control algorithm is called "High-Frequency Injection (HFI) " for internal permanent magnet synchronous motors (PMSM). In this type of motor, the magnets are not mounted on the surface of the rotor but are buried in the core of the rotor. Internal magnet synchronous motors show inductive anisotropy, which is easily seen in the relationship of the winding to the quadrant and the straight axis (Lq differs from Ld).

4 The magnetic structure of the motor

The high-frequency injection method uses the anisotropy of the magnet structure to detect the angular position of the low-speed and stationary rotor. Because the magnitude of the back EMF is proportional to the motor speed, it is too small to be detected when the motor is stationary or at very low speeds. The high-frequency injection method, based on completely different physics, can control motors operating at low speeds. A pulsating field is injected into the motor, and the electrical angle is calculated using the current in the magnetic structure of the motor. In order to avoid generating additional torque, the injection frequency must be set at a value higher than the fundamental frequency. The motor is scanned with X-rays, for example, to detect the electrical position of the rotor relative to the anisotropy of the magnet structure. This method is suitable for the stationary to low-speed phase and works in conjunction with a counter-electromotive force estimator to automatically switch the control method in real-time, depending on the motor speed. This new algorithm will fall under a number of ST's patented motor control SDK innovations for customers and offers several advantages:

- Full torque at zero speed

- Low-speed operation

- Sensorless start, no reverse rotation

- Fastest sensorless start

- Sensorless forward (clockwise) and reverse (counterclockwise) speed detection

In addition, the solution enhances the value of applications that benefit from start-up efficiency, including air compressors, low-speed operation or reverse rotation (washing machines or industrial automation, e-bikes or traction motors), and many more emerging applications.

ST's hardware tools

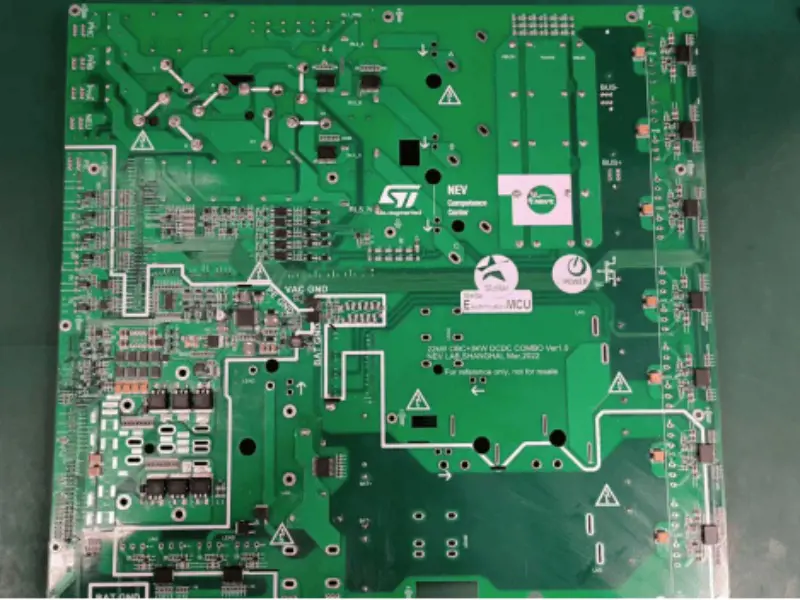

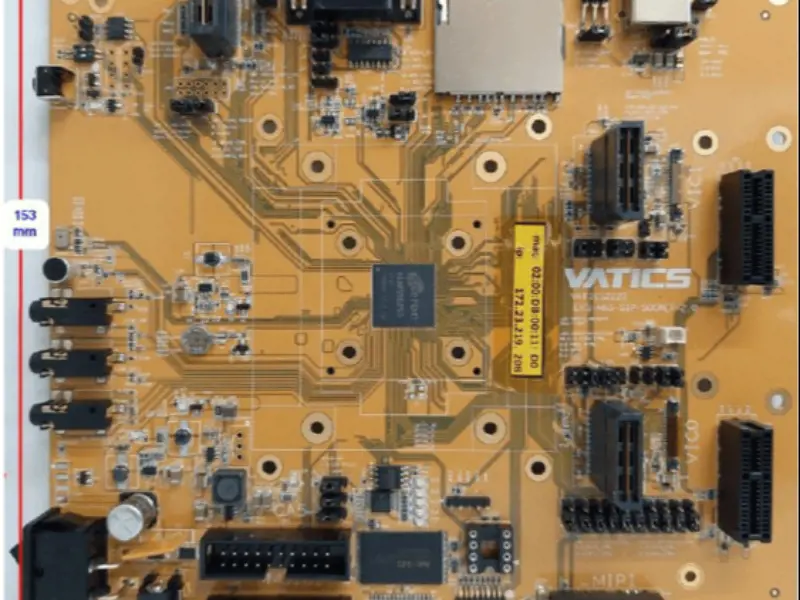

ST offers complementary evaluation boards for its motor control firmware library, enabling users to evaluate ST products, such as smart power modules (SLLIMM), IGBTs, gate drivers, motor control chips, and microcontrollers, within real motor control systems. For three-phase motor control applications, we focus on the following:

A flexible modular system consisting of a control board with any of the STM32 F0, F1, F2, F3, or F4 microcontrollers and a wealth of functional peripherals such as MEMS, temperature sensors, external memory, LCD LCDs, transceivers, cameras, etc. and a power board with SLLIMM (Small Outline Low Loss Intelligent Power Module) based ) for inverters or discrete devices for power MOSFETs or IGBTs and gate drivers. The control and power boards can be connected via ST's standard "motor control connector," ensuring full compatibility between the control and power stages.

5 Flexible system control and power boards

Single board motor drive solutions: all the functions required for motor drives are integrated on a single board, suitable for certain applications: air conditioners, ceiling fans, dishwashers, etc. The STEVAL-IHM034V2, for example, can drive a permanent magnet synchronous motor PMSM of up to 1.4kW and can drive two motors (FOC) simultaneously by connecting a single board.

Conclusion

We have outlined the new functional features of the latest version of the MC FOC SDK. ST's automation and industrial control solutions continue to add new features, technologies, and products, expanding ST's motor control ecosystem in line with the trend towards ease of use and rapid evaluation of tools while focusing on design issues such as energy efficiency, integration, and cost optimization.