Integrated Control Solutions will be the Future Trend

Update Time: Oct 01, 2020 Readership: 2327

Contents

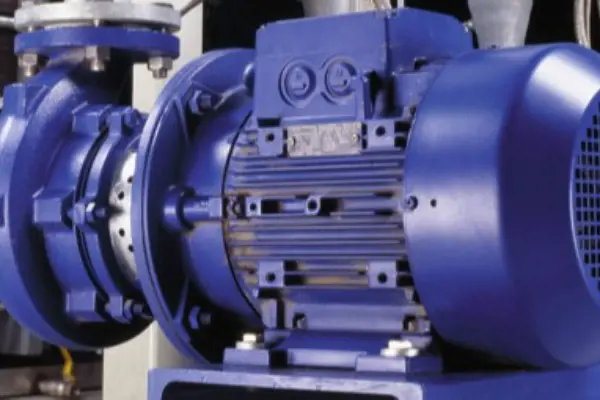

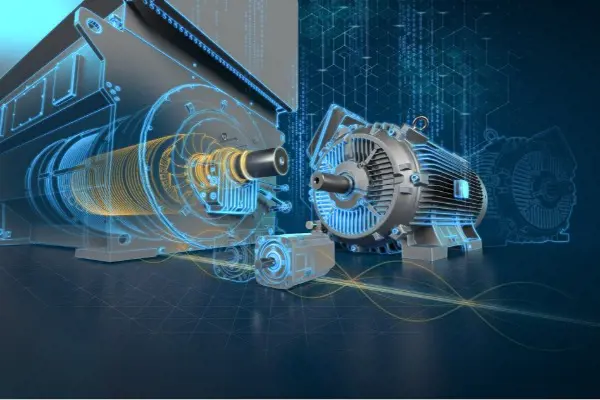

BLDC motors are becoming increasingly popular, and integrated control solutions will be the future trend. In recent years, we have seen a clear trend of BLDC (brushless DC) / PMSM (permanent magnet synchronous) motors being used in various applications such as industry, automotive, home appliances, power tools, medical equipment, and more.

This is because BLDC motors can operate at high speeds, with a speed of up to 10,000 rpm and even up to 100,000 rpm, and have low rotor inertia, allowing for rapid acceleration, deceleration, and quick reversal, as well as high power density, which can make the motor more compact. Therefore, more and more applications are adopting BLDC motors.

The efficiency of the motor is one of the important indicators, and the industry standards related to efficiency are becoming increasingly stringent. Higher efficiency requirements have led to the growth of demand for semiconductor devices (including power devices and motor controllers). The market prefers more efficient motor solutions such as BLDC/PMSM. This also drives innovation in motor control algorithms and power devices by semiconductor manufacturers.

According to Charlie Munoz, the application marketing manager of TI's BLDC motor driver product line, these new standards will prompt more customers to adopt new technologies to meet their efficiency, size, and cost requirements. Motor efficiency is an important energy-saving issue; motor power consumption accounts for a large proportion of the overall energy consumption of appliances and other applications.

Building a BLDC/PMSM motor system requires the joint efforts of motor suppliers and semiconductor manufacturers. The cost of mechanical motor assembly is too high for motor suppliers to achieve additional efficiency, so they need the help of semiconductor manufacturers to improve the efficiency of motor drivers and algorithms to optimize the system.

Mark Gill, Vice President of Strategy and Marketing at Allegro MicroSystems, also sees this trend, "We see a continuing trend of BLDC motors replacing brushed and stepper motors in industrial and automotive applications. The cost of manufacturing and controlling BLDC/PMSM motors continues to decrease, and more and more applications will choose BLDC/PMSM motors, especially for applications with higher reliability and electromagnetic compatibility requirements."

Infineon Technologies Industrial Power Control Division Marketing Director, Chen Ziying, quoted Omdia's data to indicate that it is expected that by 2024, the frequency of variable frequency for household air conditioners will reach 99%, and for washing machines and refrigerators, the frequency will also increase year by year, reaching 94% and 75% respectively by 2024.

In addition to efficiency, reliability, and robustness, the increasing trend of adopting BLDC motors in more and more application scenarios is also driven by noise sensitivity, such as some motor applications in electric/hybrid vehicle cabins. An increasing number of high-end car models are inclined to use BLDC motors.

Of course, BLDC motors can also be used in home fans, washing machine pumps, laptop cooling fans, automotive ADAS, seat cooling and ventilation, EPS and brakes, ventilation fans, server cooling fans and pumps, and other application scenarios.

BLDC/PMSM motor drive methods and selection tips

Currently, there are various control solutions for BLDC/PMSM motors. According to Tristan Scott, a product marketing manager for motor control solutions at ON Semiconductor, from the perspective of device integration, there are discrete power devices and integrated modules, independent drive solutions without MCU participation, and SoC solutions that integrate controllers, drivers, and power devices. They are suitable for different application scenarios. From the control perspective, the control solutions for BLDC/PMSM motors include sensor and sensorless trapezoidal algorithms, sine, and magnetic field orientation. Sensor solutions benefit from low cost and ease of commutation, while sensorless solutions can save circuit board space and improve system stability by eliminating sensor failure risks.

Specifically, different solutions can be selected according to system speed, torque, and position requirements. Charlie Munoz of TI pointed out that the trapezoidal algorithm is a low-cost, easy-to-implement control algorithm with low processing requirements. Still, it has a significant torque ripple compared to sine and magnetic field orientation control. Sine is a highly efficient and ultra-quiet solution, but it is more complex than the trapezoidal algorithm and is prone to higher switching losses. Finally, the magnetic field orientation control FOC has higher torque and motor efficiency and lower noise and torque ripple compared to other commutation methods.

Tristan Scott of ON Semiconductor believes that sine wave control and FOC have more application scenarios. Traditional trapezoidal wave control is slowly being replaced in some scenarios requiring high efficiency and low torque ripple.

In terms of specific products, some manufacturers provide discrete hardware solutions, while others provide integrated solutions. For example, according to Yan Jungang, a product marketing manager for advanced solutions at ON Semiconductor, in terms of power devices, ON Semiconductor can provide discrete IGBT, MOSFET, and SiC MOSFET for low to medium power applications, as well as IPM modules (integrated power devices and drivers) for medium to high power scenarios. IPM modules can help customers save PCB space, optimize heat dissipation and EMI performance, and shorten development time. In terms of control, they will provide a range of 3-phase drivers and fully integrated (MCU+driver+power devices) SoC solutions. In many scenarios, fully integrated solutions can effectively reduce the overall size of the motor and simplify customer development difficulty.

TI's BLDC products include discrete gate drivers and integrated gate drivers. The integrated gate driver controls FET and easy-to-operate gate drivers, allowing customers to adjust the motor within ten minutes. Its main advantages are quiet and smooth motion control, orderly system integration, high efficiency, high power density, expandable power supply and packaging, and extremely reliable.

TI offers four steps to simplify the selection process to make selecting BLDC products easier. Each step requires selection based on power level, architecture, motor control type, interface, and integration requirements. Ti's brushless dc motor driver considerations and selection guide provide reference recommendations for the best brushless dc solution. Ti's website provides simple selection tools such as parameter search, portfolio visualization, and simple use case content around featured applications to help customers easily select the right device.

New motor control technology and future trends

With the development of BLDC/PMSM motor control technology, several new products and technologies have emerged, such as high voltage, sensorless control, sinusoidal and directional control, and motion health monitoring. Different companies also have different strategies for dealing with them.

According to TI's Charlie Munoz, TI quickly adapts to power demands by developing innovative integrated control solutions, such as motor parameter extraction tools. The complexity of BLDC motor design requires smooth integration and drive of software algorithms with hardware components. Ti is taking proactive steps to reduce design time and effort by providing one-stop solutions, code-free integration of sensorless control drivers, tuning guides, and GUI platforms to help quickly evaluate and tune motors for maximum efficiency. "We also offer application-specific designs where we can reduce noise by 2-3dB with techniques such as deadband compensation and PWM modulation," he noted.

ADI expressed their views on motor control trends for smart manufacturing. They believe combining technologies is needed to achieve the next generation of intelligent motion control solutions for smart manufacturing. When combined, these technologies can provide reliable, accurate motion control for demanding industrial deployments, with access to system information from advanced inspection. This requires a combination of technologies in precision measurement, isolation and interface, industrial Ethernet, magnetic sensing, power management, machine health, and more. For example, to support next-generation drives and motors that enable complex motion control, digital isolation technologies are required to provide isolated data and isolated communication interfaces such as RS-485, USB, and LVDS. Insulated gate drivers are also required to drive high-end and low-end power semiconductors to provide reliable, secure, and highly reliable assets. Gate drivers convert logic-level PWM signals into high-end reference signals for controlling power transistors. High voltage inverter applications typically use IGBTs, with a future trend towards SiC and GaN to increase switching frequency and reduce switching losses.

Infineon has used its manufacturing expertise and long experience to develop a SiC trench process that circumvents planar gates' gate oxygen reliability problems. Considering the short-circuit tolerance motor drives require for power switches, Infineon's chips have 2-3 microseconds of short-circuit capability. The products are packaged in industry standard TO247 package and SMD package TO267-7 package. Infineon also offers Easy 1B and Easy 2B packages of SiC MOSFET three-phase bridge power modules, which result in small parasitic parameters and high power density. In addition to overall higher efficiency and lower losses, the higher switching frequency achieved by SiC technology directly benefits external and integrated servo drives in a more dynamic control environment. Changing motor load conditions make this possible with faster motor current response.

ON Semiconductor has also developed SiC MOS-based TMPIM modules for inverter applications, which can reduce inductor coil size and improve thermal performance. Together with its DTFC algorithm, this is the industry's first advanced motor control solution to be implemented on the M0+ platform, allowing engineers more options.

When it comes to future trends, integrated solutions are generally favored. As fierce competition inevitably drives more innovation, integrated solutions help customers reduce system size, improve reliability, and reduce development cycles, making this trend even more favored by the industry.

Daniel Torres, product line director for Allegro MicroSystems' motors business, explains that one future trend is integrating motor drive solutions at the highest level, with the benefits of smaller PCBs, smaller motors, and cost-optimized designs. And through functional integration can reduce the number of ICs required in the system, reducing the system's demand for various resources and reducing current consumption, thereby directly improving system efficiency.

He also pointed out that increased integration can reduce the need for other components and the bill of materials (BOM), providing more flexibility for customers. Increased integration can also reduce time-to-market by simplifying design. In the case of Allegro's motor drives, the high level of integration eliminates the need for verification and corner analysis when implemented in a system, enabling further system optimization.

Daniel Torres believes that future innovations may further reduce the system BOM by integrating features typically found in microprocessors, allowing customers to remove the microprocessor from the system eventually.

Microprocessor vendors are beginning to integrate more and more analog and power devices into their microprocessor products. Some are solidifying algorithms into their products to make development easier, and BOM costs lower for their customers.

Conclusion

The motor control industry is moving to higher efficiency, lower noise, and more robust systems. This shift will allow more customers to transition to BLDC/PMSM motor systems. With the popularity of smart manufacturing and the rise of Industry 4.0, motors are assuming the core role of power output, and the requirements for motor control are increasing. Especially in the precision manufacturing industry, how to have excellent motion control capability will become a hot topic in the motor industry, specifically in the program. It needs the support of various chips and programs such as low drift, high precision, and high transient. In addition, durability/reliability/safety will also be increasingly important, especially with the rapid increase in motors. Rapid maintenance is more and more important. And all these need strong support from chip manufacturers.

When it comes to future applications, as the industrial and automotive markets continue to show more electrification trends, BLDC/PMSM is likely to see growth, and there may be more developments in the industrial appliance market, such as vacuum cleaners, pumps and fans, and other noise-sensitive applications in the home environment. In addition, the BLDC/PMSM automotive market may have more applications in hybrid/electric vehicles, which puts higher demands on motors' high efficiency and low noise.

Extended Reading

- Exploring the Power and Precision of Brushless Motor Controllers

- How Electric Motors are Changing the Automotive Industry?

- Control Techniques for Electric Motors: Optimizing Performance and Efficiency

- Revolutionizing Electric Mobility: The Synergy of Cyberquad Motor Controller and Tesla's Innovation

Popular Blogs

-

Exploring the Power ...

Brushless motor controllers are advanced electro...

-

How Electric Motors ...

With rapidly development in technology, electric...

-

Control Techniques f...

Discover how advanced motor control software, va...

-

Revolutionizing Elec...

Central to Tesla's success is its relentless pur...